3D printing systems for industrial applications

Printing systems from innovatiQ are versatile: Whether complex individual part or series parts – you always get an impressive result!

Manufacturing process

Build chamber size

TiQ 2

The compact entry to industrial 3D printing!

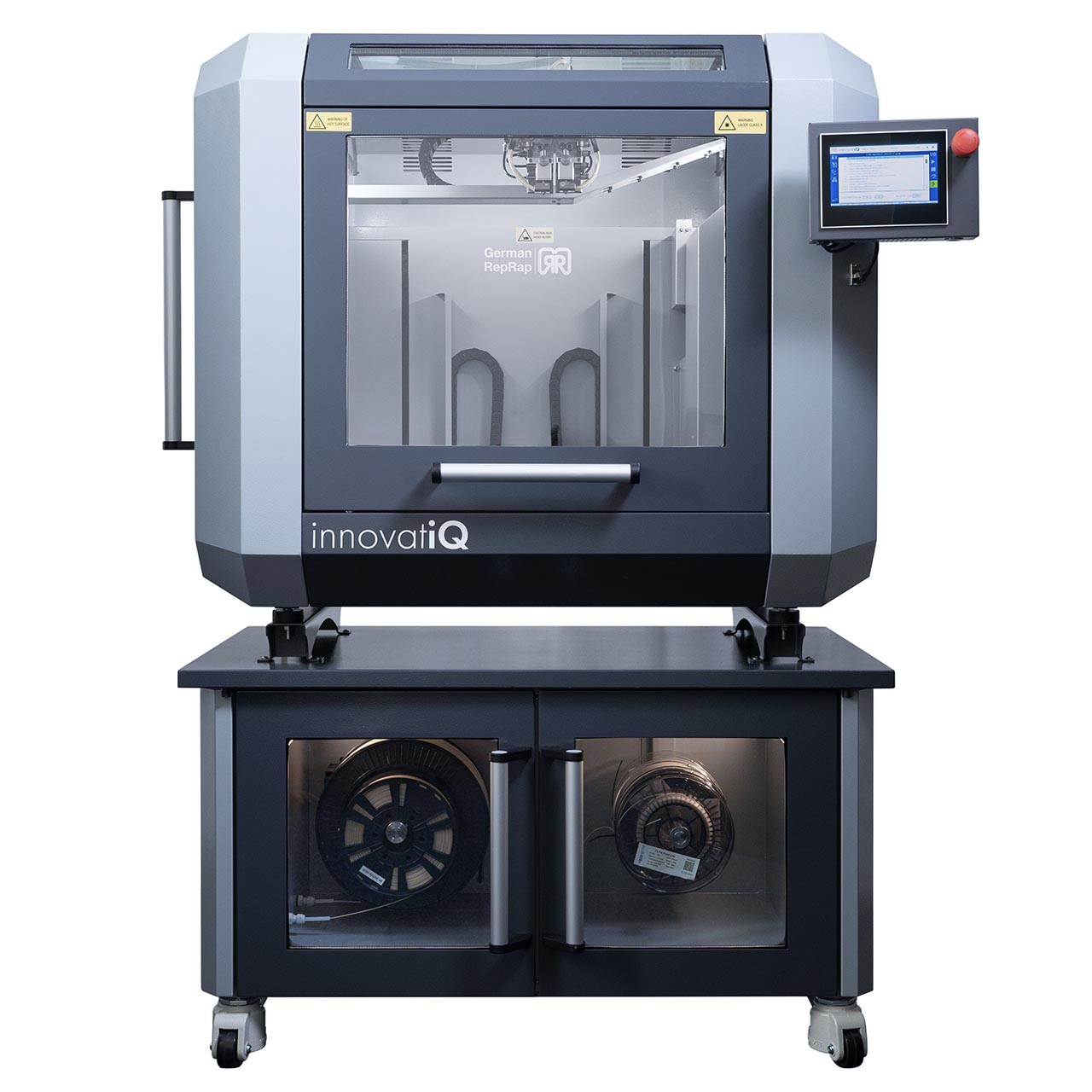

TiQ 8

High Temp - Infinite Options! The Allrounder for additive printing

LiQ 5

Additive manufacturing with standard silicone (LSR)

TiQ 5

High productivity with maximum process reliability - packed into an XXL build space!

LiQ 320

Additive manufacturing with injection molding silicone - get creative!

3D printers for industrial applications

We use two different technologies with our industrial 3D printers. As the pioneer company in silicone printing and manufacturing systems for the liquid standard LSR silicone (Liquid Additive Manufacturing). We also offer industrial 3D printers that use filament material (fused filament fabrication). If you need to produce elastic parts, the LAM process is well suited. For solid, durable components we recommend FFF. Do you need to produce large-size components? Our printers have large build space, you can use the same printer to produce both large and small size components.

Industrial 3D printers for every need

Our 3D industrial printers offer customized solutions to your production needs. With our open material policy, you can choose any filament material, pre-dry it with our MiQ 5 material drying unit and get optimized results. Do you need to add color to your products? You can with our LAM system. With SmartColoring system, you can apply high transparency (% 0,5 by volume) or high color density. (Up to % 2 by volume) to your end products. According to your application needs. You can additively manufacture end-use silicone components in small series.

3D Printing applications for a wide variety of industries

InnovatiQ industrial 3D printers offer a wide range of use. Additive manufacturing technologies are used in a wide range of industries. All industries can use 3D printing in prototyping or for small series. Whether in the automotive industry, aviation, or toolmaking – our industrial printers play a role wherever it is a question of producing components with high process reliability. The durability of the components produced from fiber-reinforced materials would convince you. Be it near-series prototypes or XL components in small series – you will be impressed.

Additive manufacturing: sustainability without compromising quality

3D printing with filaments is more sustainable manufacturing technology than conventional methods. Material is only applied wherever is needed and only the exact amount necessary for the production.

Sustainability is an important issue for 3D printing material choice. Ofcourse you can also process recycled filament. Our open material platform gives you the freedom to choose. Look at our material finder. If you cannot find what you are looking for here, simply contact us. We are happy to test materials for you or print sample parts on request. Contact us!