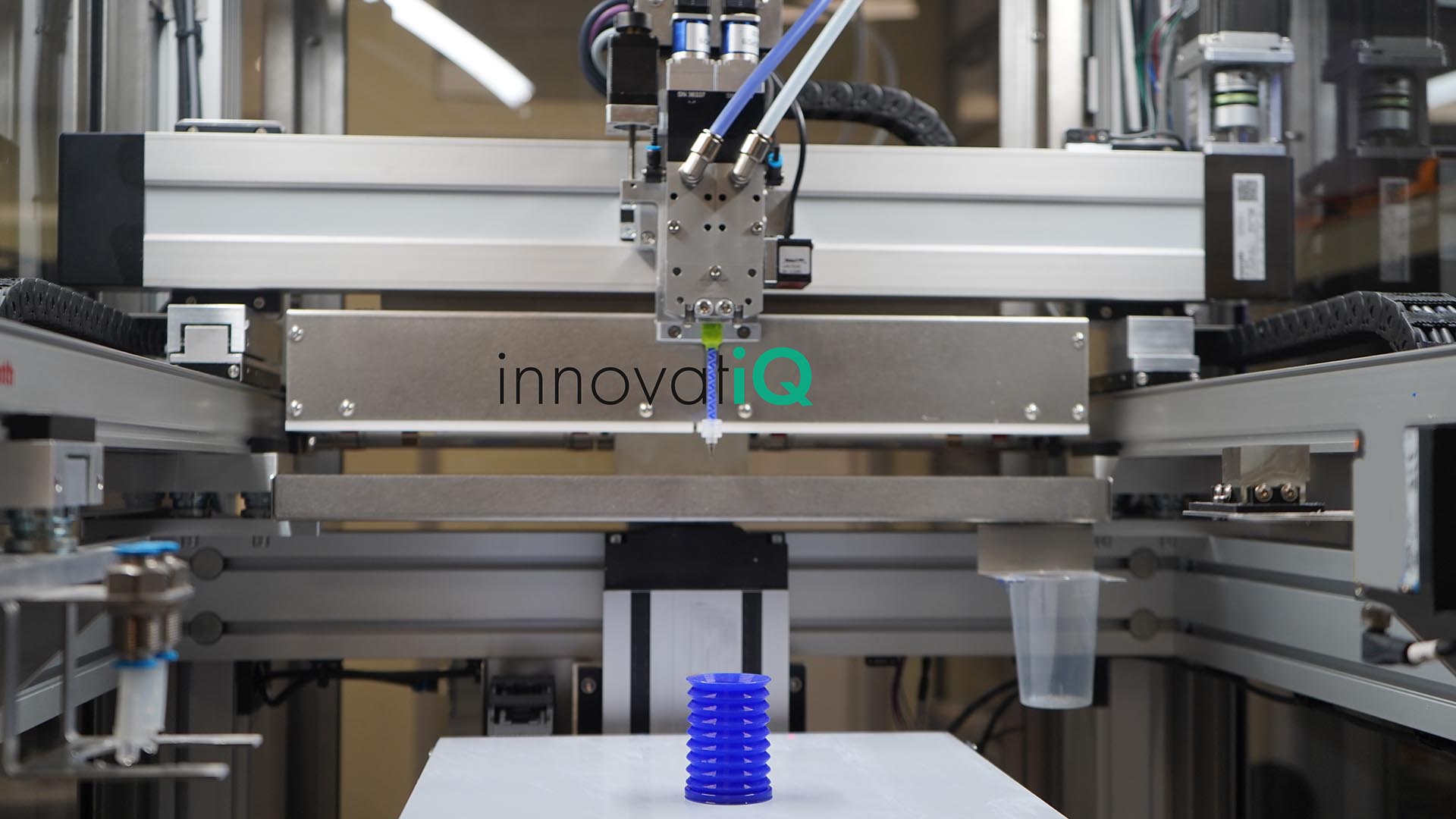

LiQ 320 – 3D printing from liquid silicone

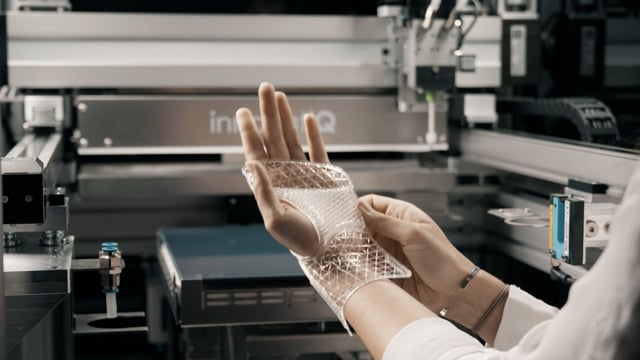

The LiQ 320 is the solution for additive manufacturing of components from liquid silicone. Both prototypes and functional parts can be produced in comparable

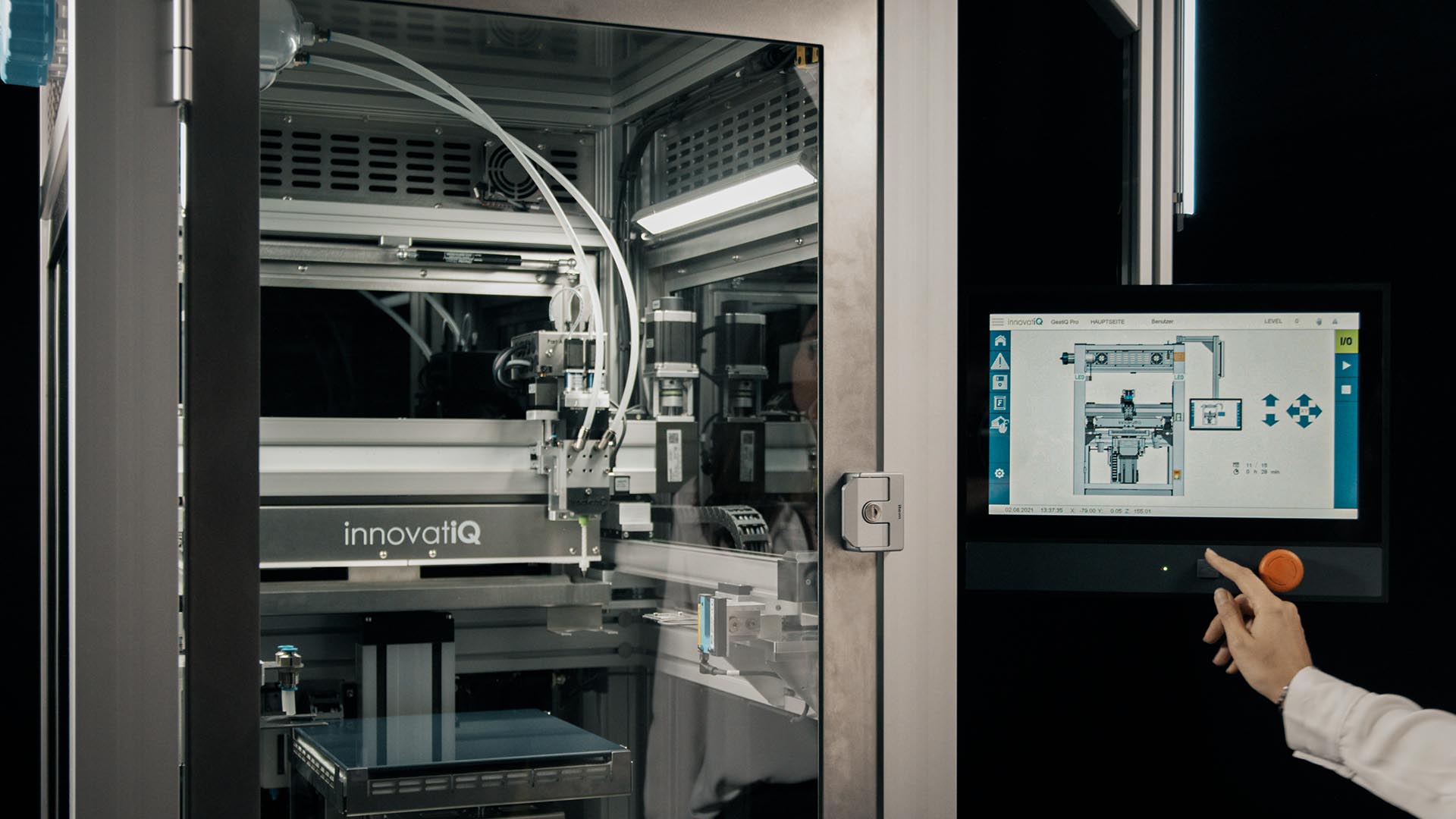

- Intuitive operation

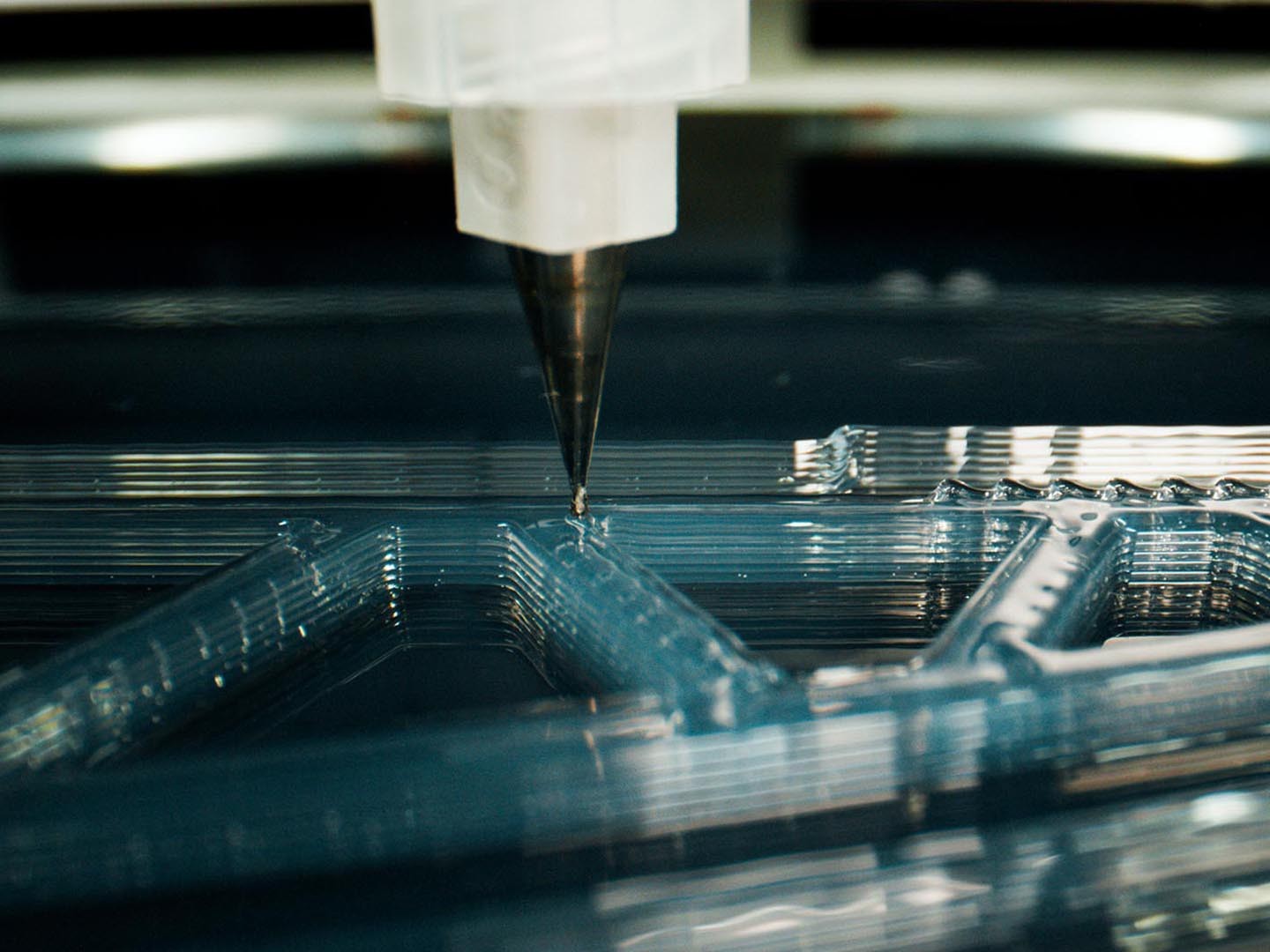

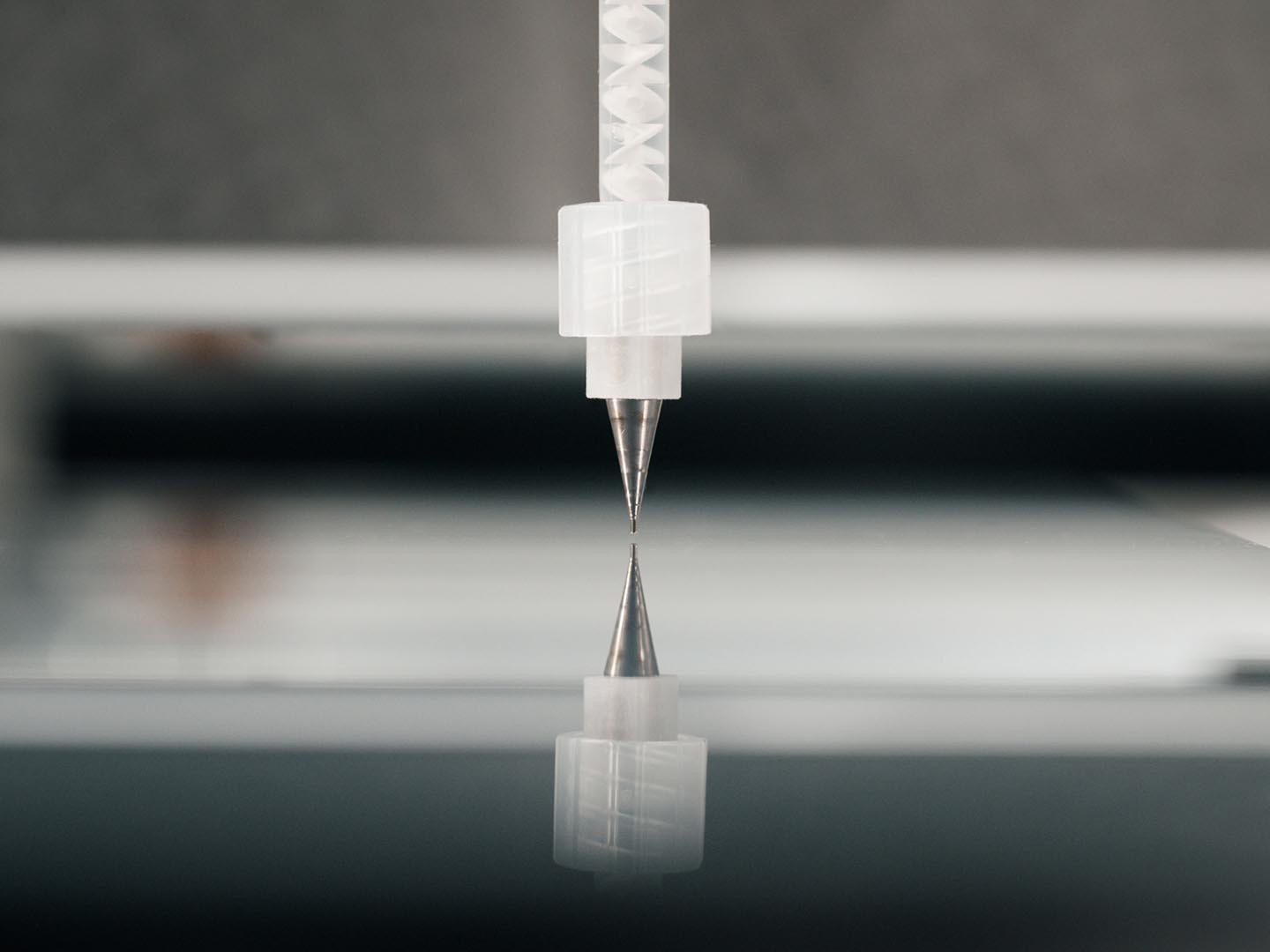

- Precise material application

- Integrated material crosslinking

- Reach your goal faster with Smart Functions

- Time-saving production

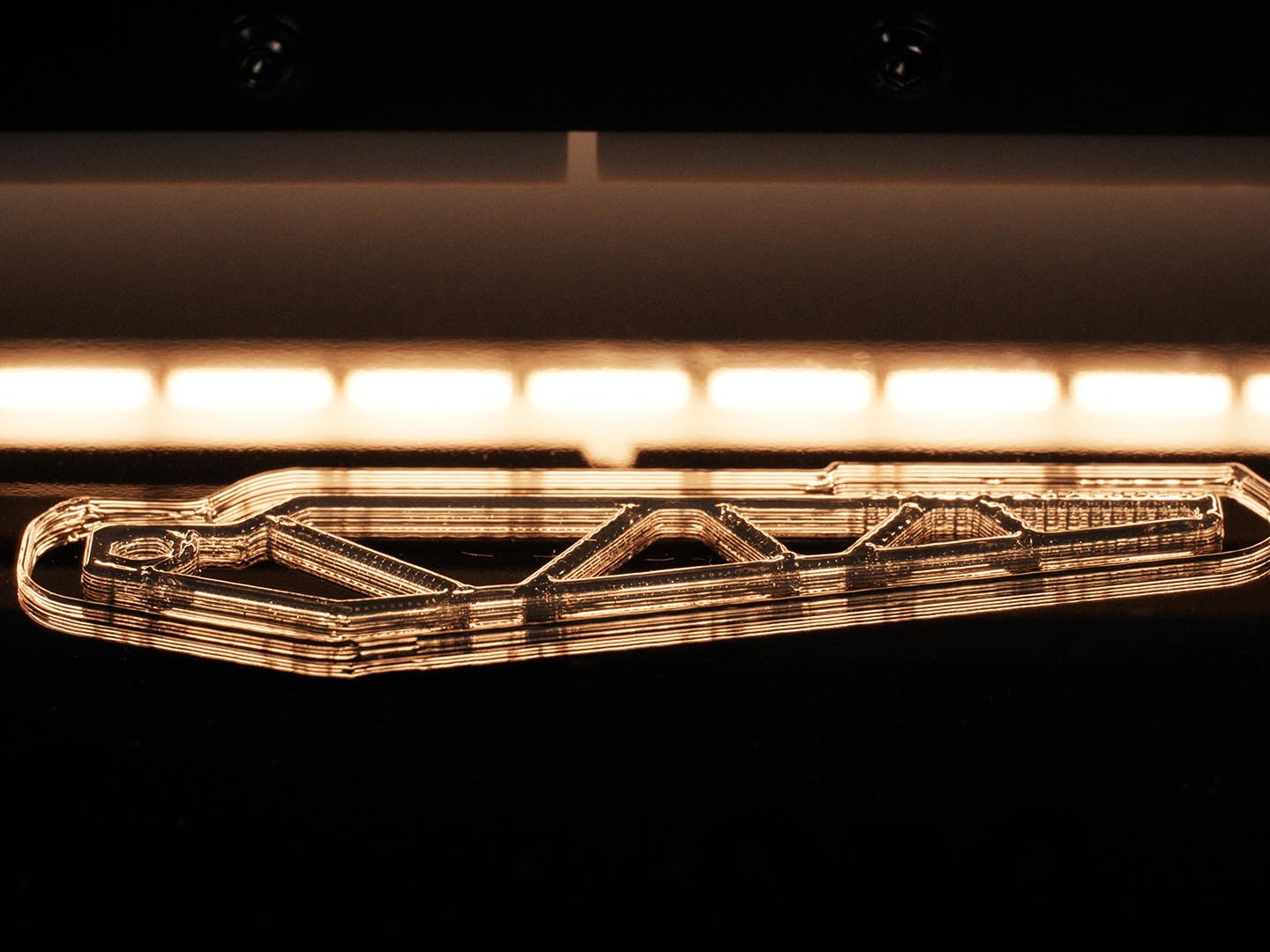

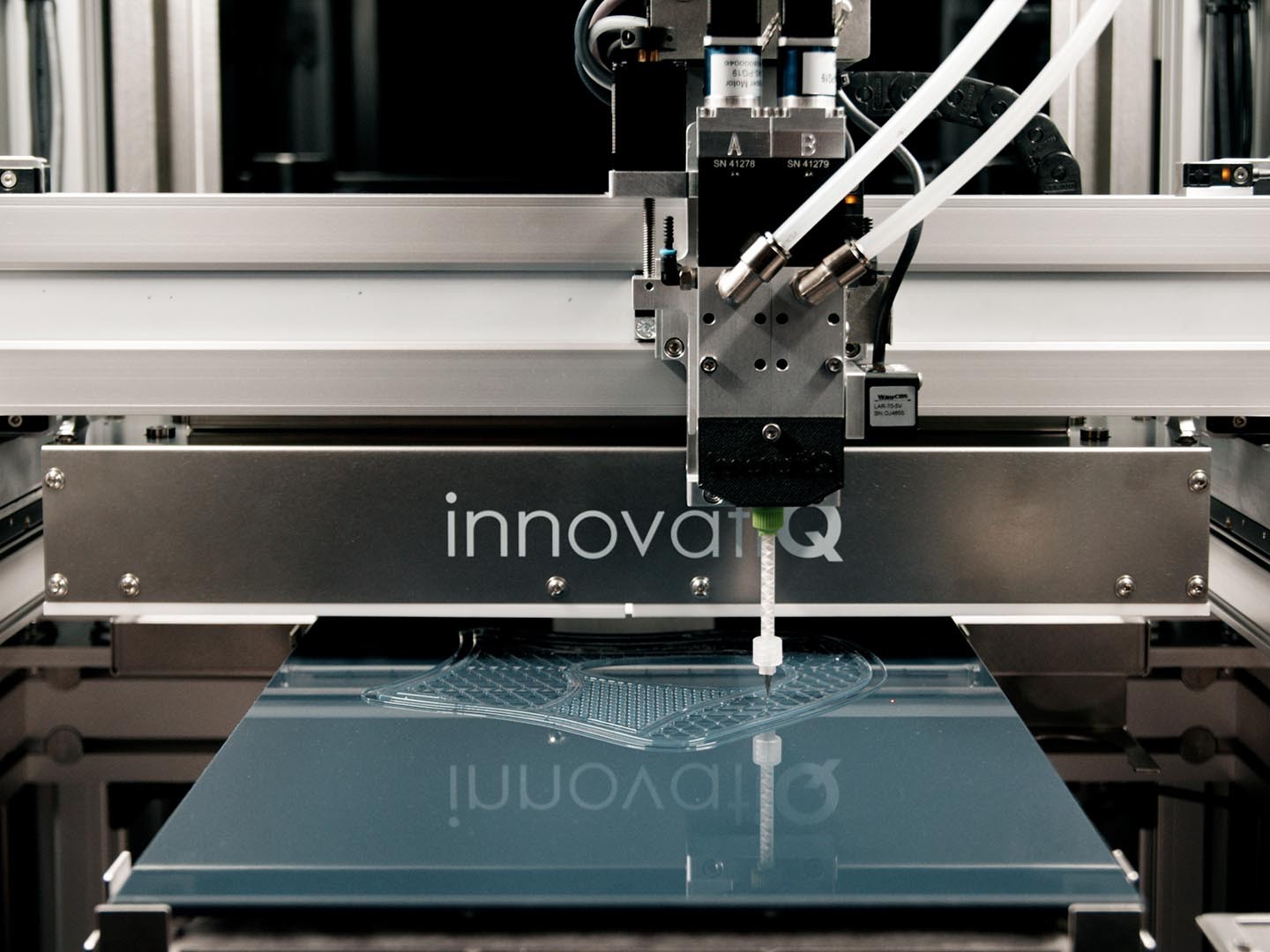

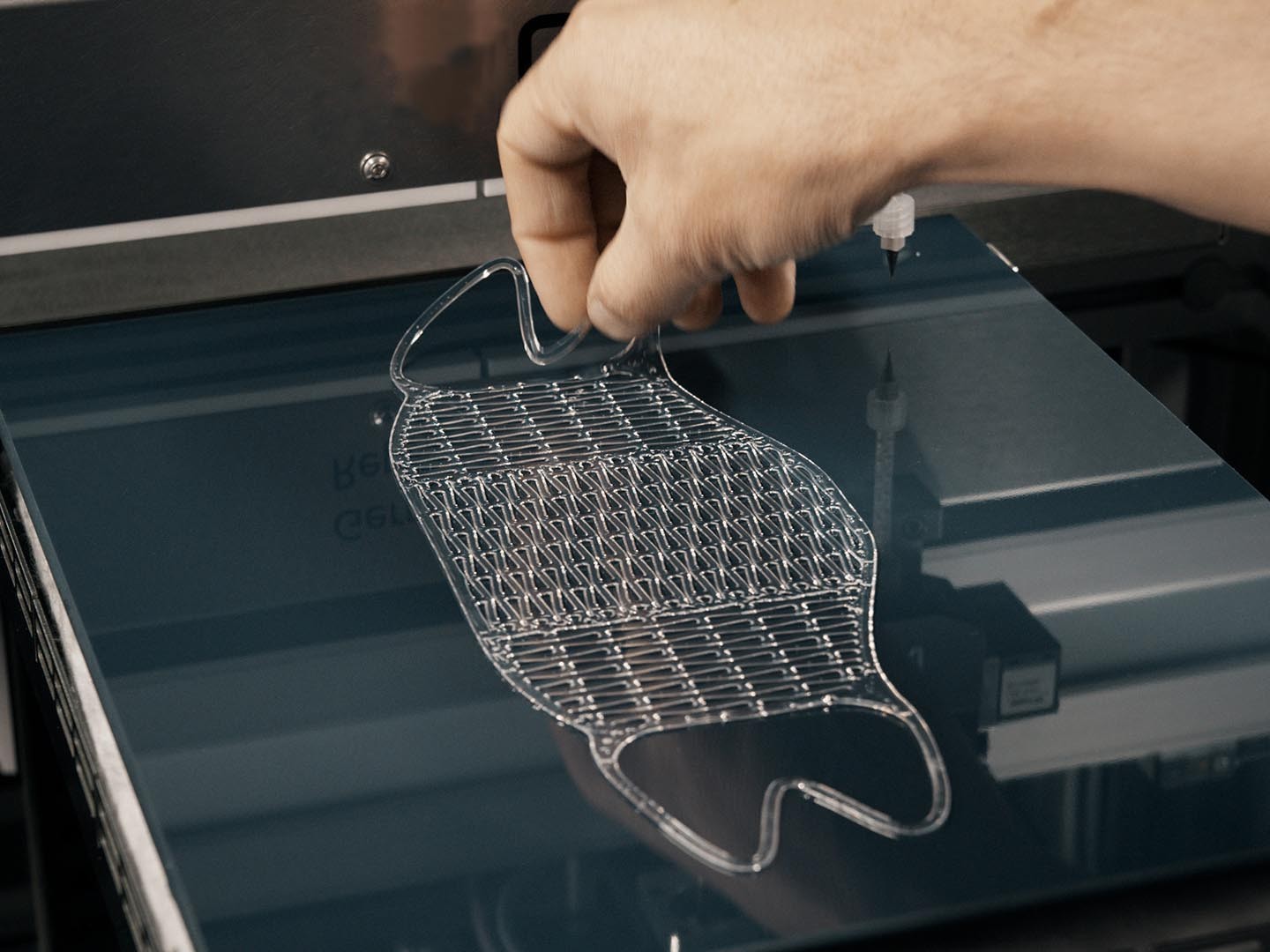

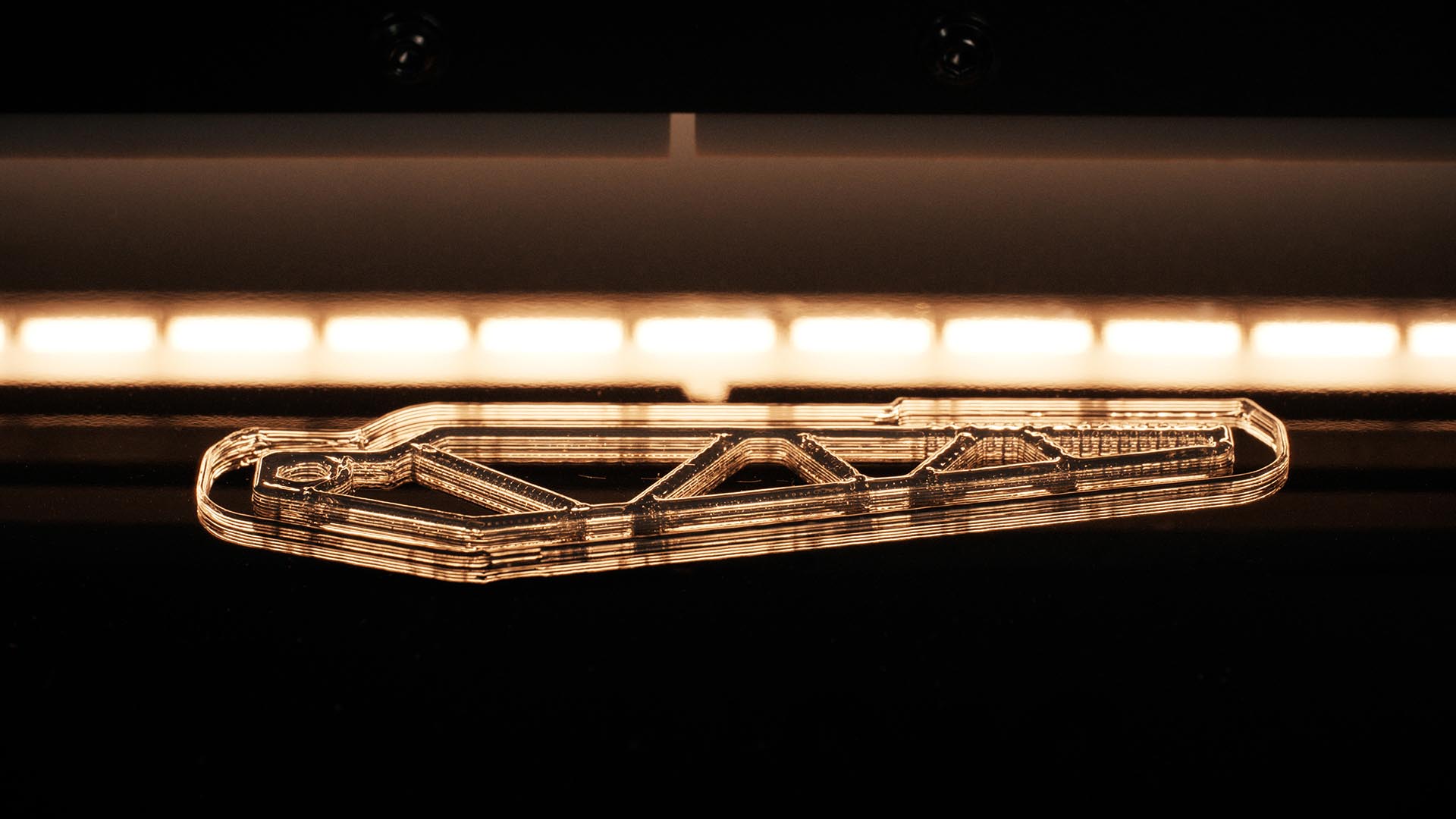

Complex geometries, completely new freedom of form!

Cross, grid or honeycomb structures, many things are possible. Geometries that were previously impossible to implement with conventional manufacturing technologies can now be mapped.

The structure of the object can be controlled at the molecular level. With the LAM process, the

Technical data

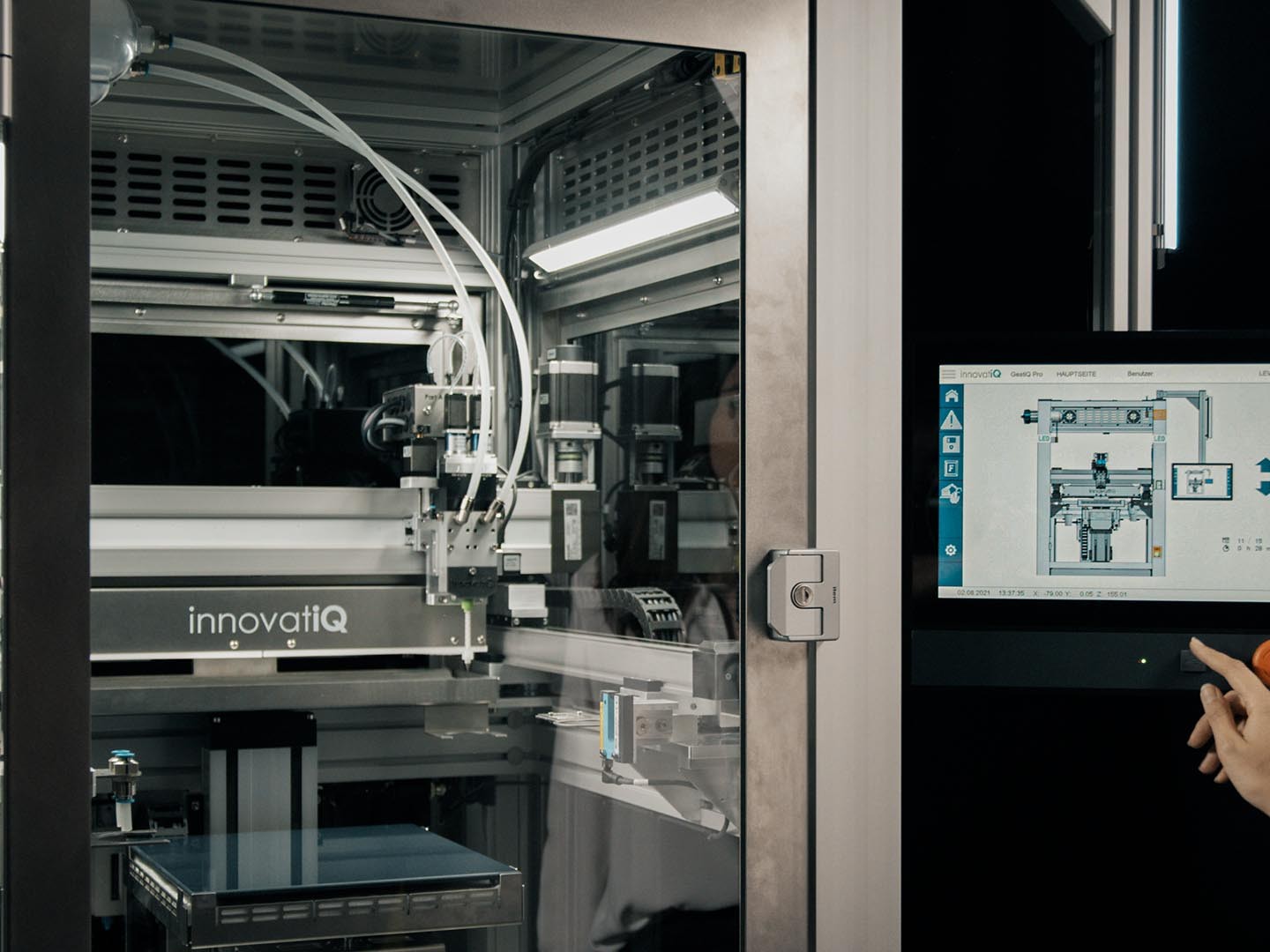

The HMI touch panel allows intuitive operation and contributes to reliable operation of the LiQ 320.

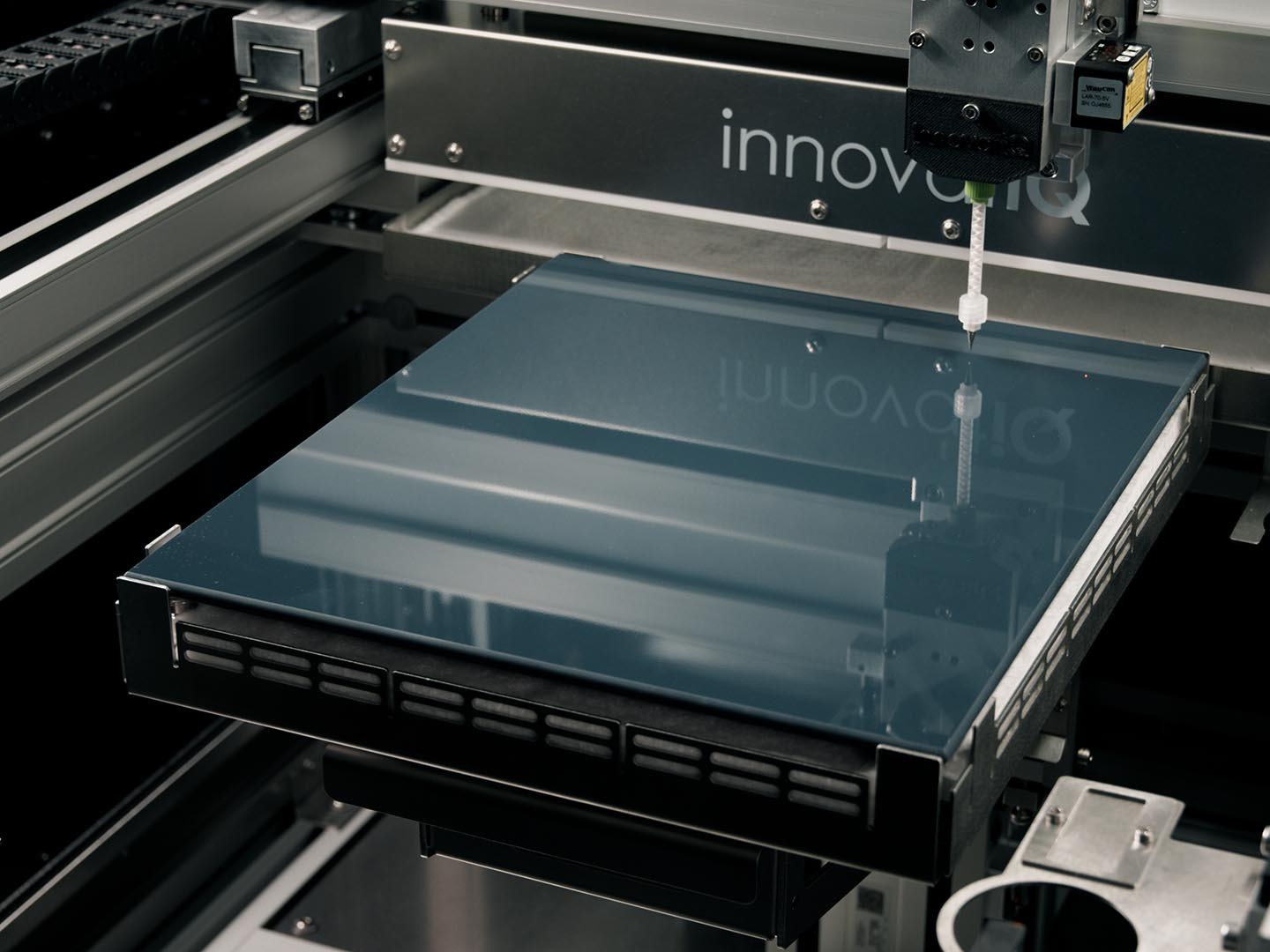

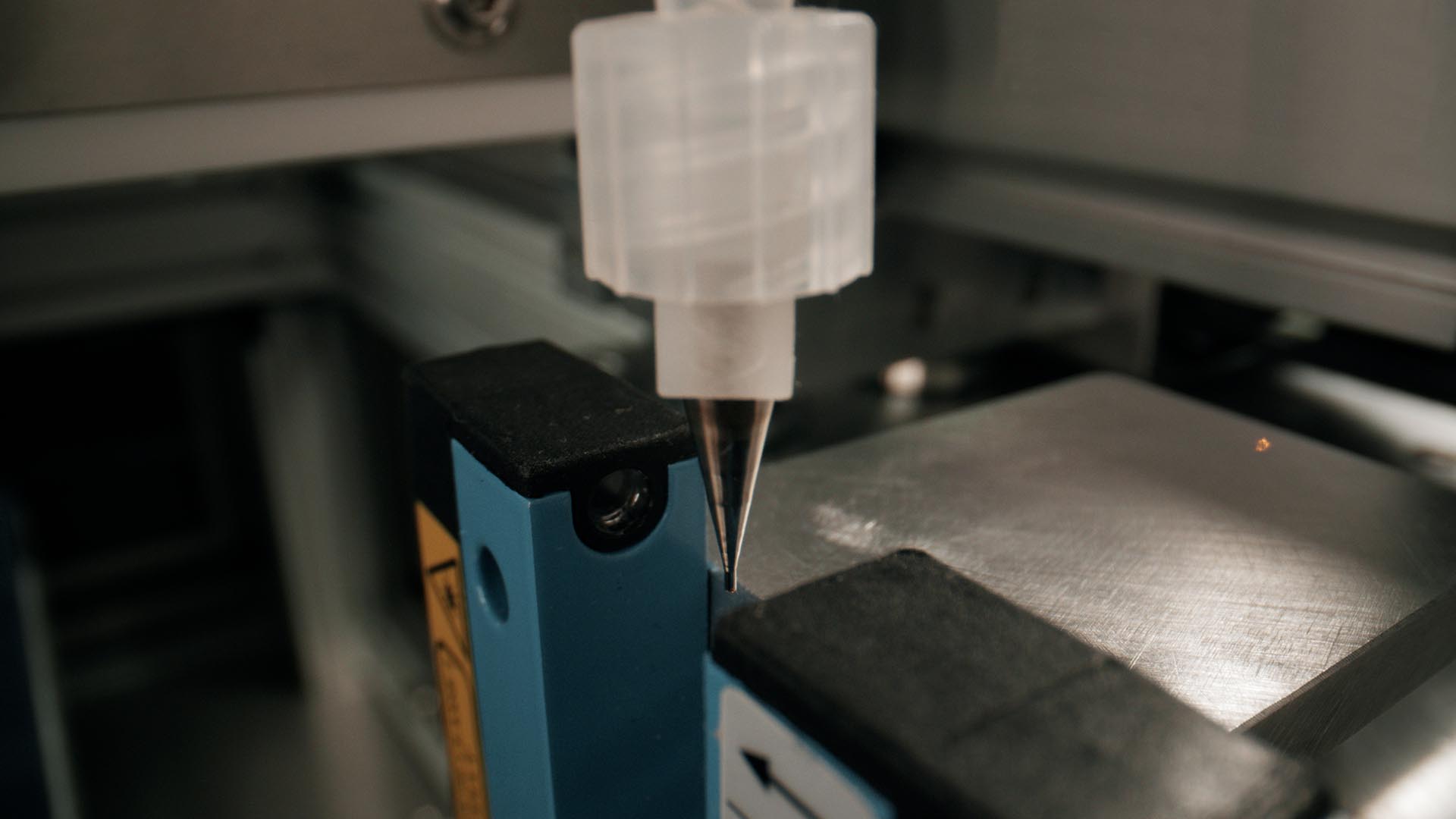

With the LiQ 320, additive manufacturing with high process speed and distortion-free 3D printing is possible for any geometries. Thanks to process-controlled volumetric extrusion, the material application is precisely defined and implemented.

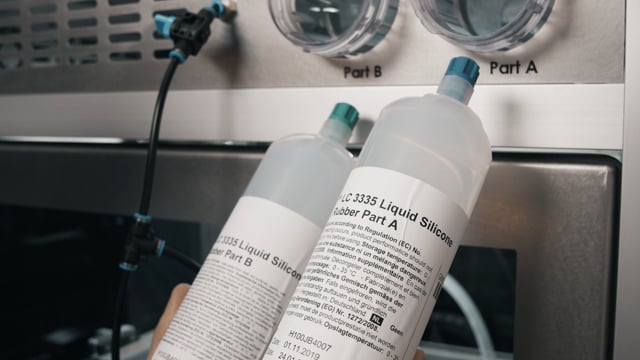

The curing of the material is integrated into the production process.

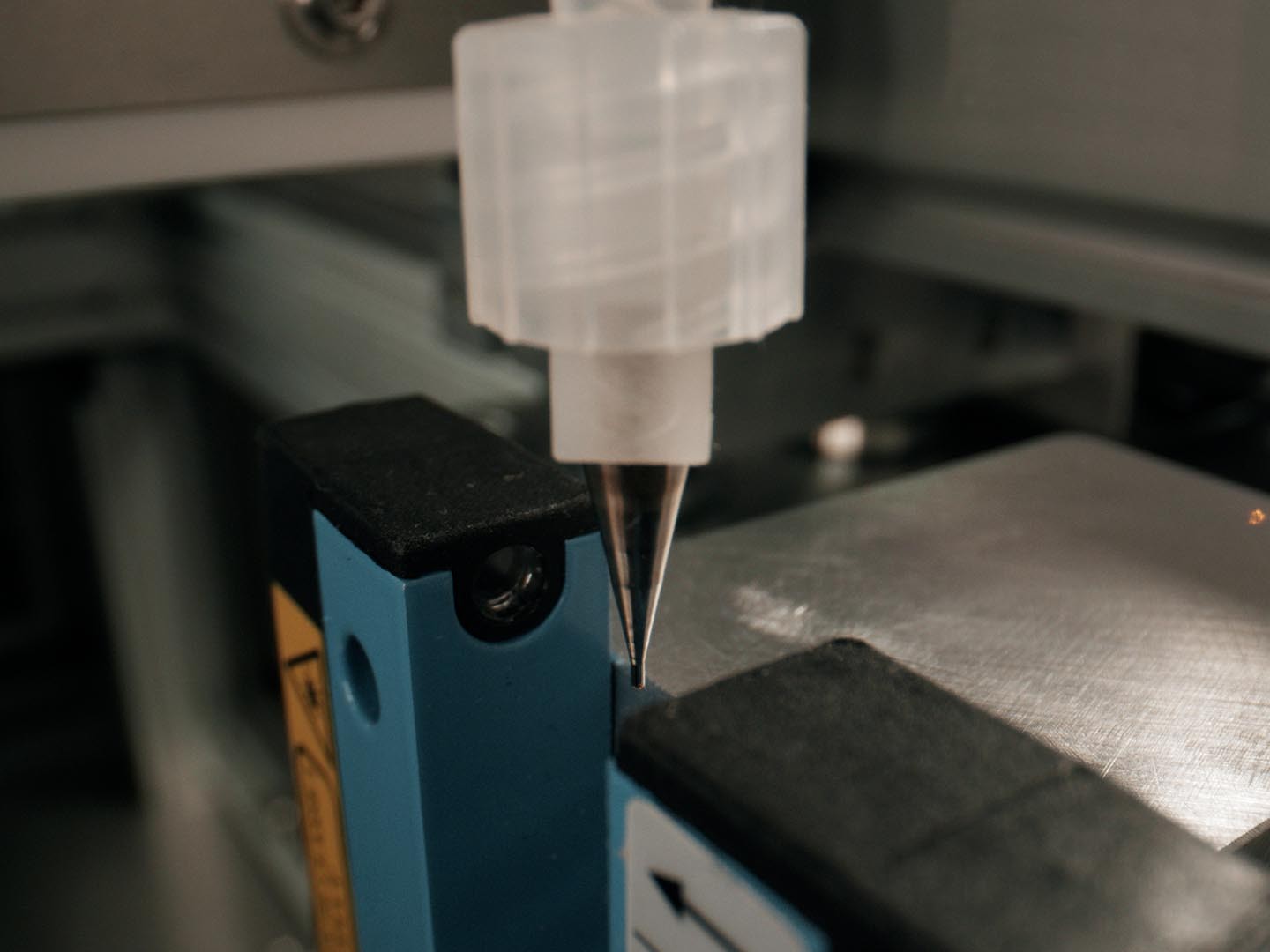

Both the nozzle change and the leveling of the print bed are automatic thanks to the intelligent SmartFunctions.

The material change is completed in just a few steps. The components are fully functional and ready for use immediately after the printing process without any post-processing.

Technical Features

- Print space* (X/Y/Z): 250 x 320 x 150 mm

- printing speed*: 10 – 150 mm/s

- Traversing speed*: 10 – 300 mm/s

- Repeatability* (X/Y): +/- 0.2 mm

- Layer thickness* (min.): 0.22 – 0.9 mm

- Nozzle options*: 0.23 | 0.4 | 0.8 mm

- Consumables*: SILASTIC™ 3D 3335 Liquid Silicone Rubber (LSR).

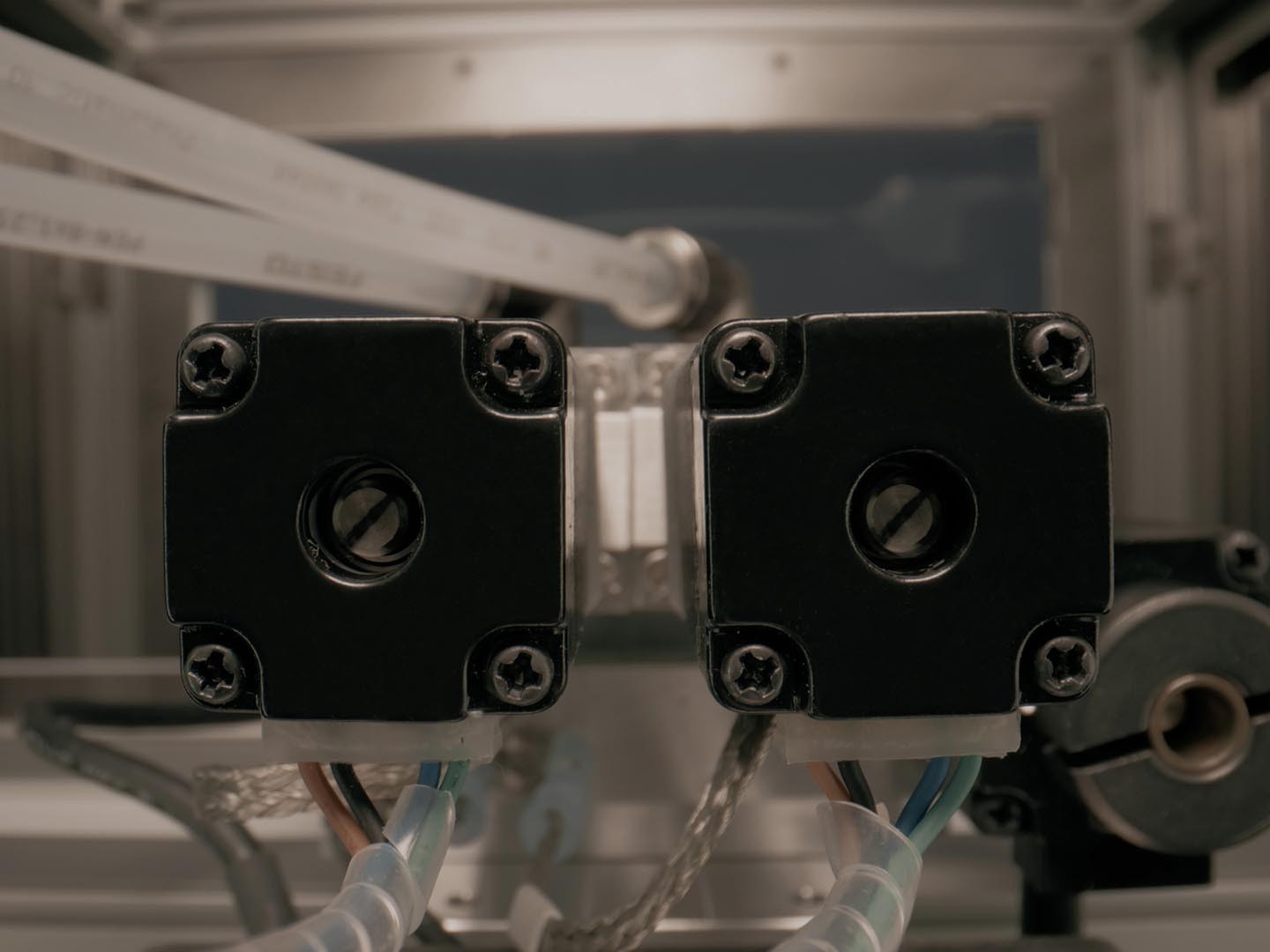

- Extruder: lifting and countersunk head, volumetric extrusion

- Options: Maintenance contract, barrel removal

- Data exchange: stand-alone printing with touch display, network-compatible

- Software equipment: Simplify3D

- Power consumption (max.) 2.3 kW, approx. 50% in continuous operation

- Connected load**: 230 V, 16 A

- Display: 7 inch touch

- External dimensions (W/D/H): printer without cartridge system and display: 800 x 960 x 1957 mm

- Weight: approx. 350 kg (without cartridge system)

- Technology: LAM (Liquid Additive Manufacturing)

- Lamp temperature: ca. 2.000 °C

- Material crosslinking: ca. 200 °C

* may vary depending on material and component geometry.

** deviating in different countries

Liquid Additive Manufacturing by innovatiQ!

Here you can find more information about Liquid Additive Manufacturing (LAM) by innovatiQ!