LiQ 5 – New and more convincing: Printing with standard LSR silicone

As innovatiQ, we are the pioneer for Liquid Additive Manufacturing. And with the LiQ 5, our LAM technology is already in its 4th generation. The LiQ 5 3D printer is ideal for the additive manufacturing of components made from standard LSR silicone.

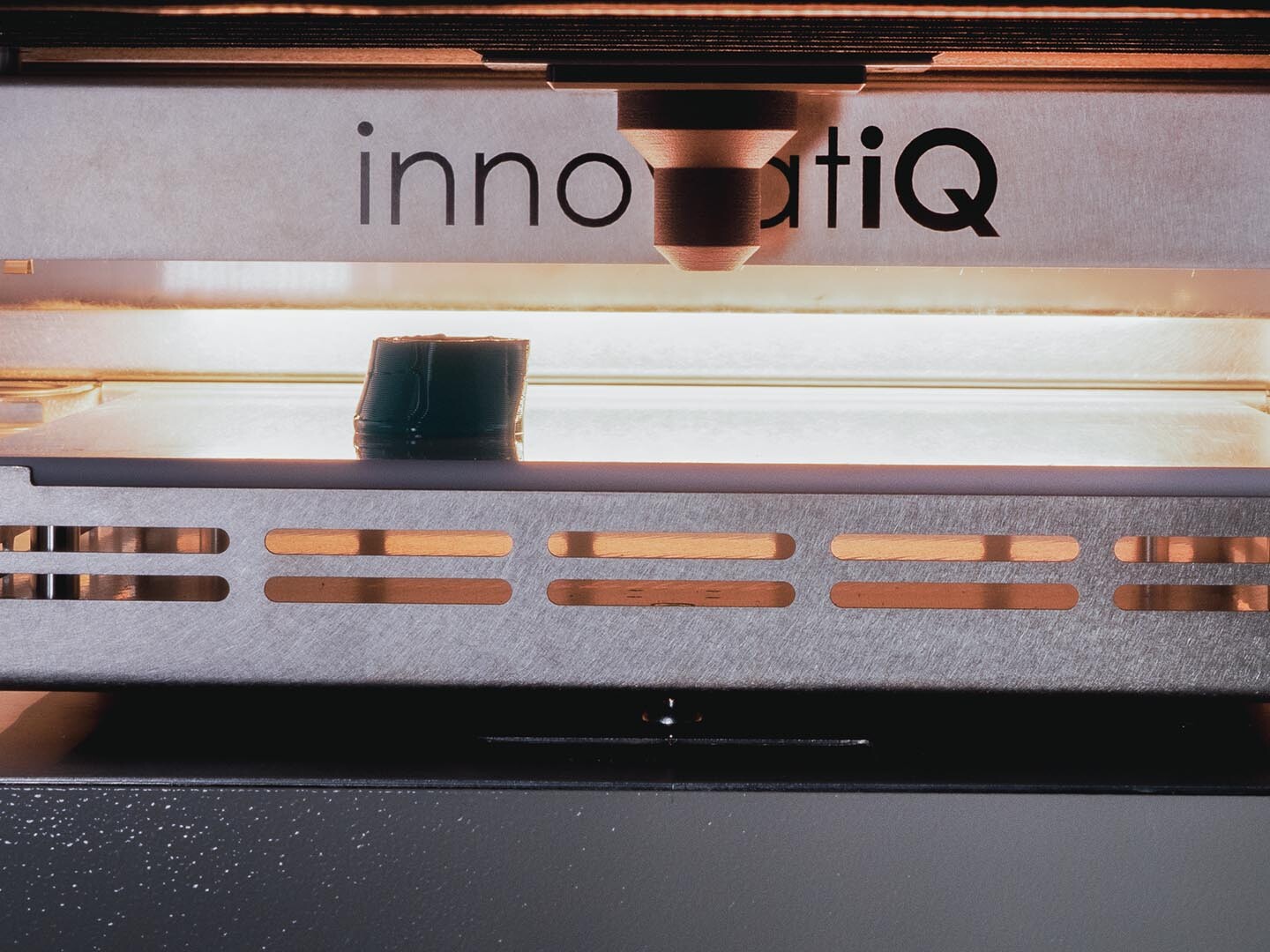

The LiQ 5 has an actively heatable build chamber that supports the printing process. In the LiQ 5, heat can thus be metered into the printing process and waste heat removed again. The result is components made of LSR material that are second to none in terms of surface finish and quality.

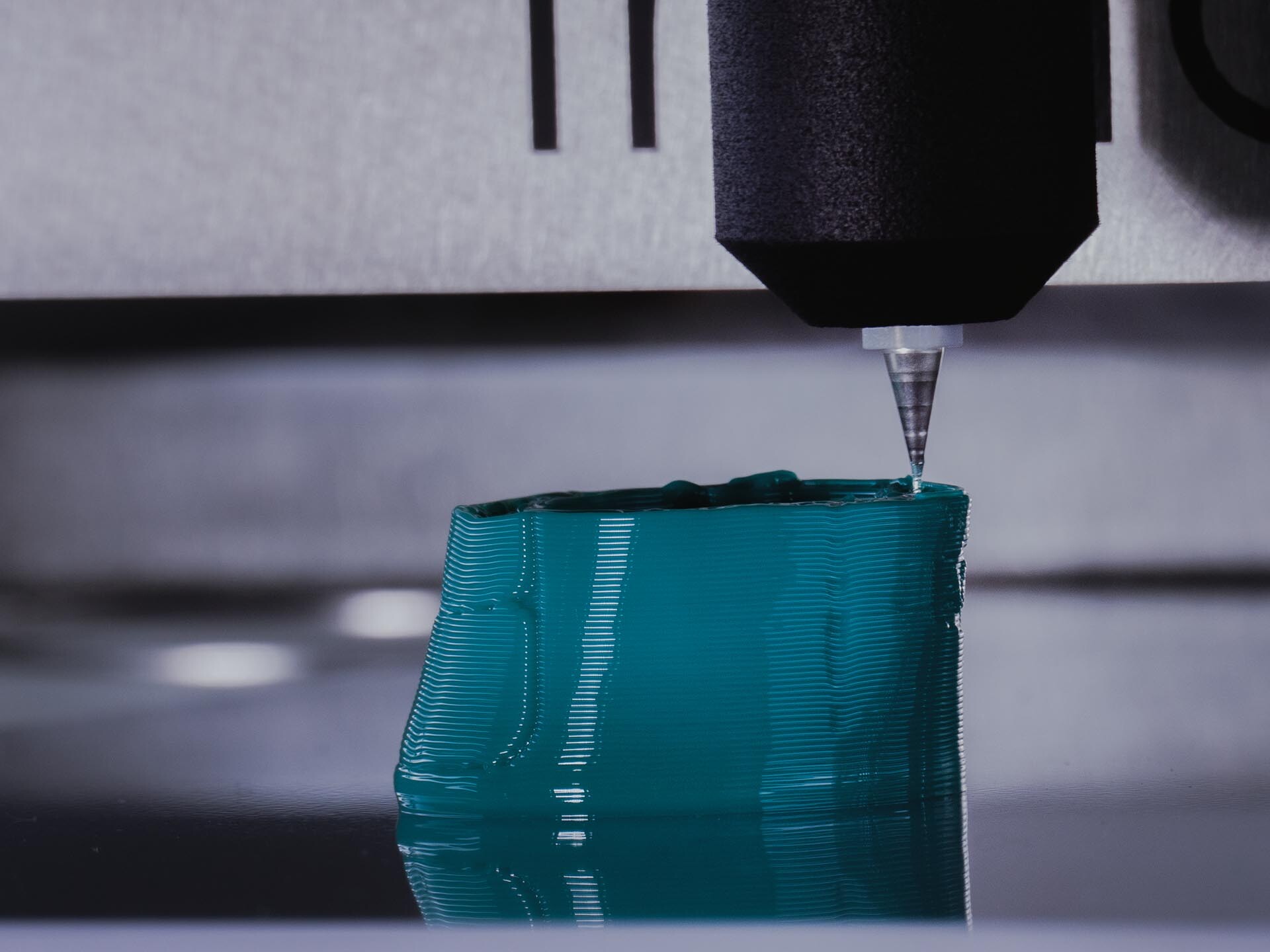

With the patented innovatiQ LAM manufacturing process, it is possible to produce both prototypes and functional parts with comparably good material properties compared to the injection molding process. In particular, because of its high process reliability and a print result without post-processing, for almost all types of geometric components, the LiQ 5 is considered a gamechanger among silicone 3D printers.

- Actively heated chamber up to 80 °C

- Intuitive operation

- precise extrusion

- Patented integrated thermal material crosslinking

- faster on target with SmartFunctions

- Multiple applicability

- SmartColoring

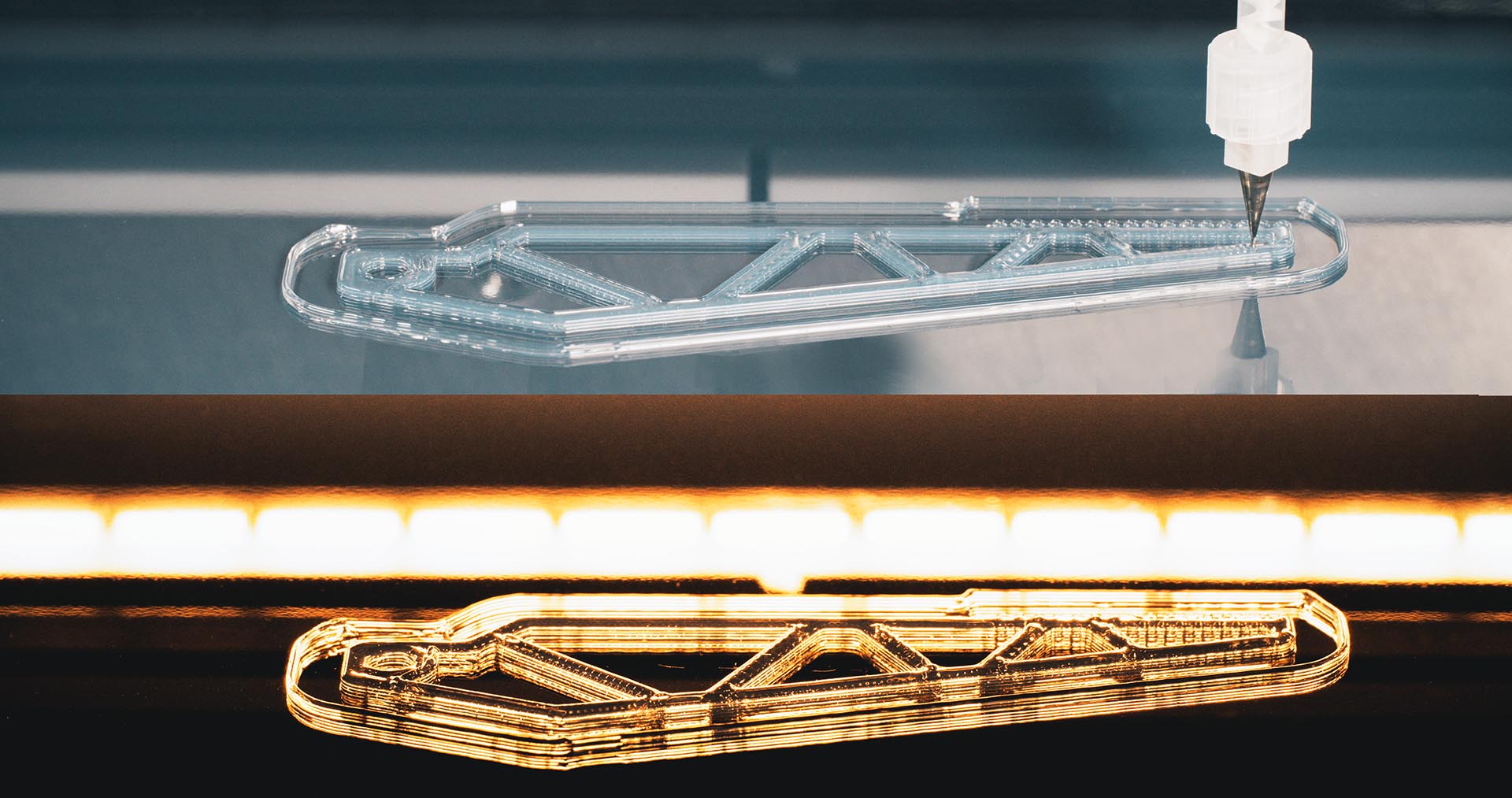

No worries thanks to freedom of shape!

With the freedom of shape in 3D Printing comes also the ease of manufacturing. With the LiQ 5, your design or prototyping department has a whole new set of options.

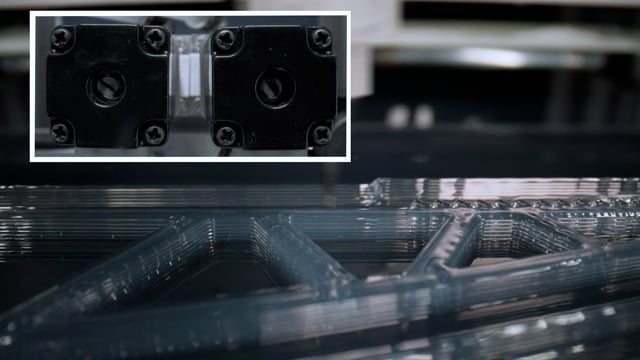

New: optional 2nd print head for printing with support material!

This makes it possible to produce almost any shape – even complex ones. Thanks to our LAM production technology, you can get 3D printed silicone components to market faster – without injection molding tools and without post-processing.

Technical features

The CNC control “GestiQ-Pro” allows intuitive operation and contributes to reliable operation of the LiQ 5 silicone 3D printer.

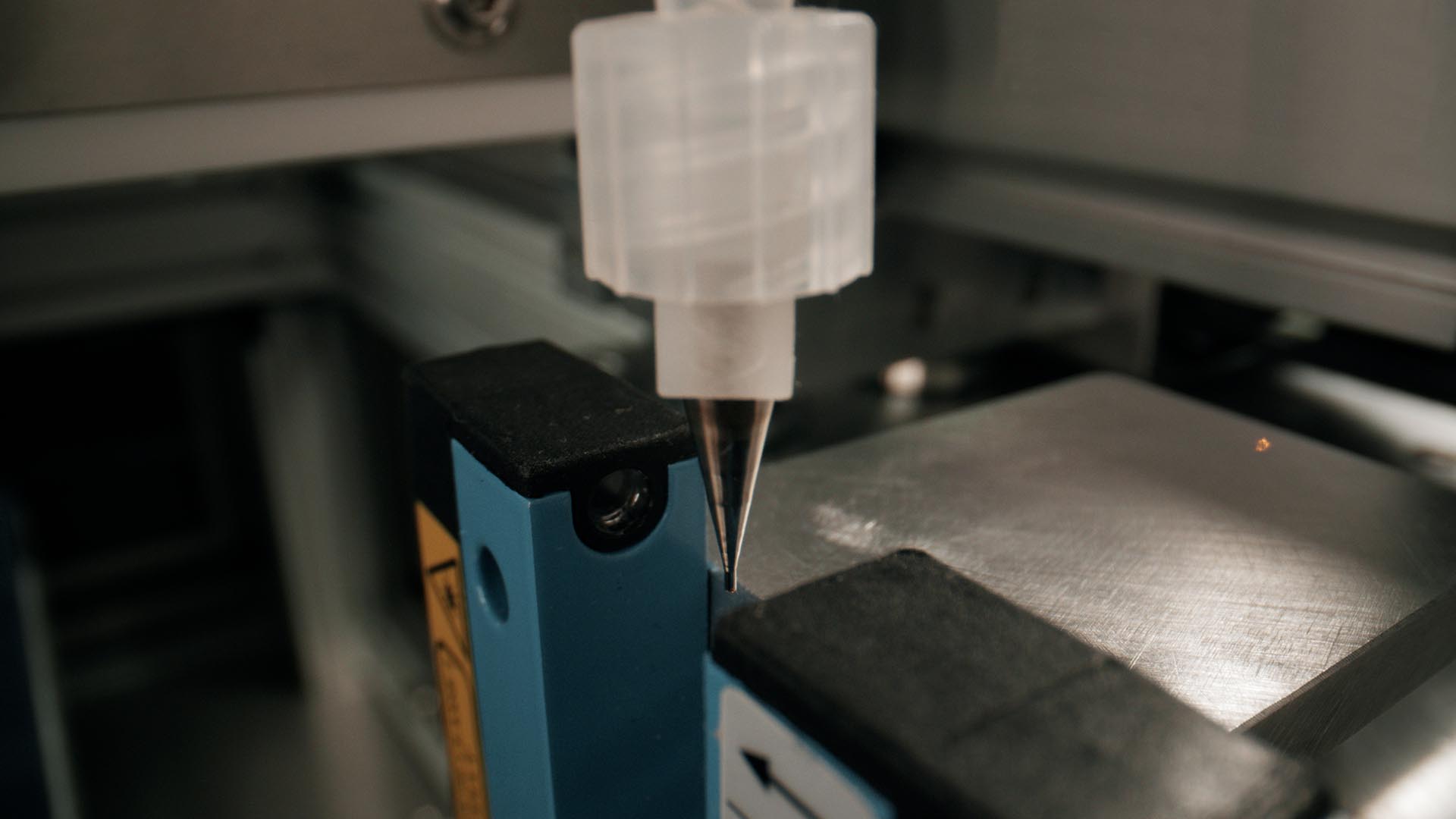

With the LiQ 5, additive manufacturing with high process speed and distortion-free 3D printing is possible for almost all geometries. Thanks to process-controlled volumetric extrusion, the material application is precisely defined and implemented.

The curing of the material is integrated into the production process.

LiQ 5 with automatic calibration: Both nozzle change and print bed leveling are automatic thanks to the intelligent SmartFunctions.

The material can be changed in just a few simple steps. The components are fully functional and ready for use immediately after the printing process without any post-processing.

Technical data

- Build chamber (X/Y/Z): 250 x 320 x 150 mm

- HMI: GestiQ-Pro with 12-inch-Touch-Display, network capable

- Print speed*: up to 150 mm/s

- Traversing speed*: up to 200 mm/s

- Repeat accuracy* (X/Y): +/- 0,05 mm

- Layer thickness* (min.-max.): 0,15-0,9 mm

- Nozzle diameter:* (min.-max.): 0,15-0,9 mm

- Material*: Liquid Silicone Rubber (LSR), Shore 30A / 50A

- Build chamber: actively heated up to 80 °C

- Temperature Material crosslinking: Process-dependent

- Data exchange: stand-alone printing with touch display or network-compatible

- Software-Slicer: Included

- Power consumption (max.): 2.3 kW, approx. 30 % in continuous operation

- Power Supply: 230 V, 16 A (EU); 110 V, 20 A (US)

- Dimensions (W/D/H): 1208 x 940 x 1968 mm

- Weight: ca. 600 kg

- Technology: LAM (Liquid Additive Manufacturing)

- SmartColoring: incl. metering unit

* Variations depending on equipment/material/process