TiQ 5 – 3D printing for high-performance thermoplastics

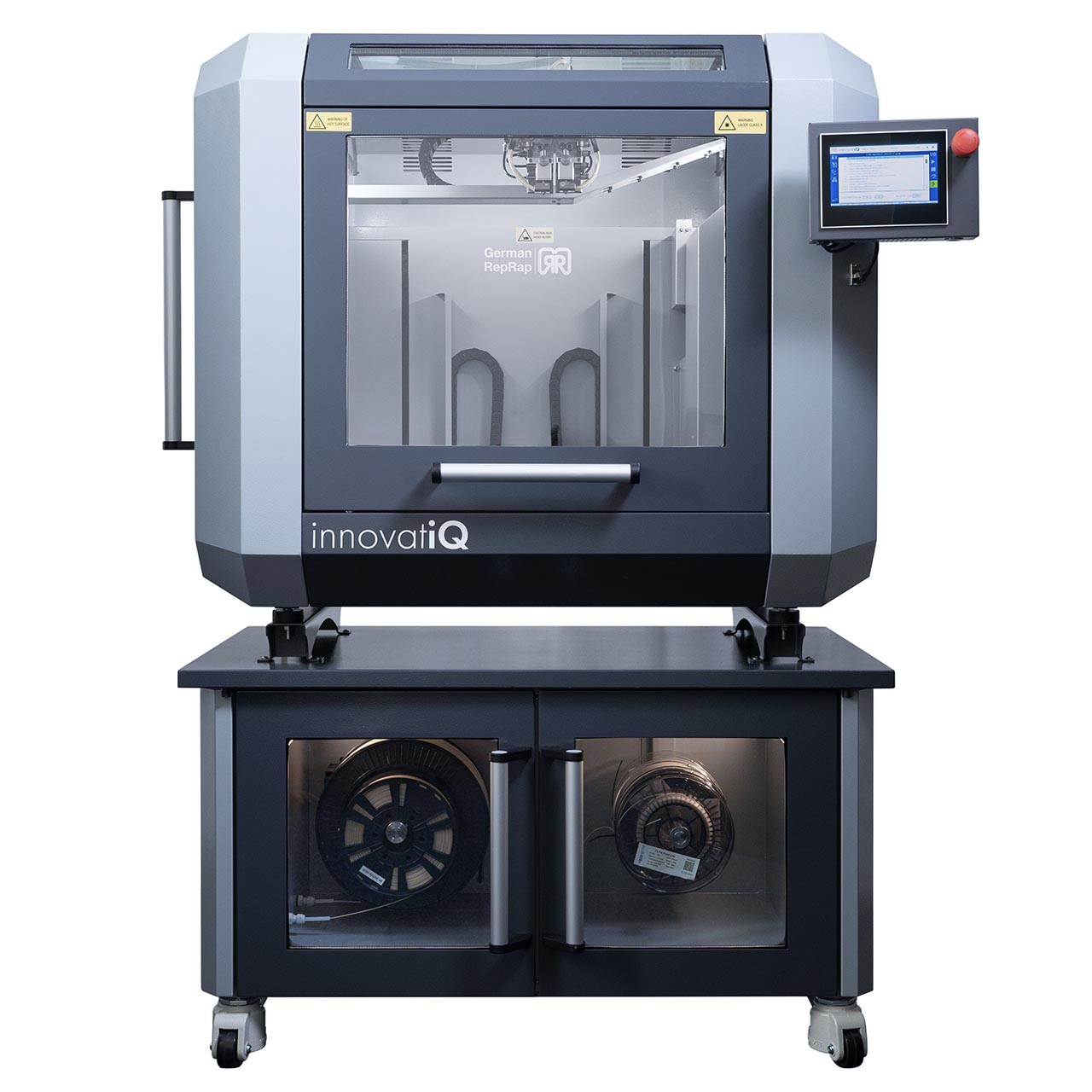

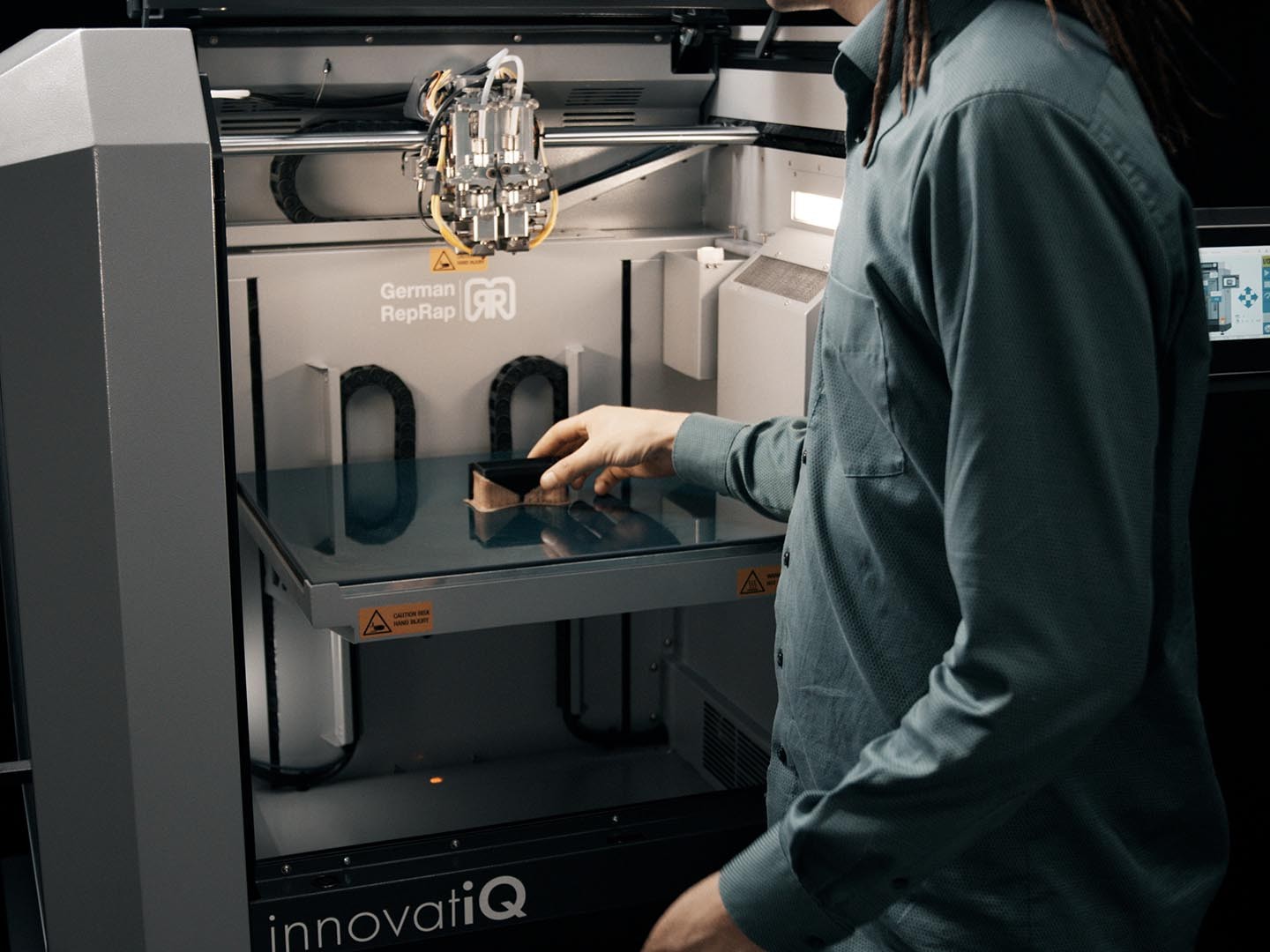

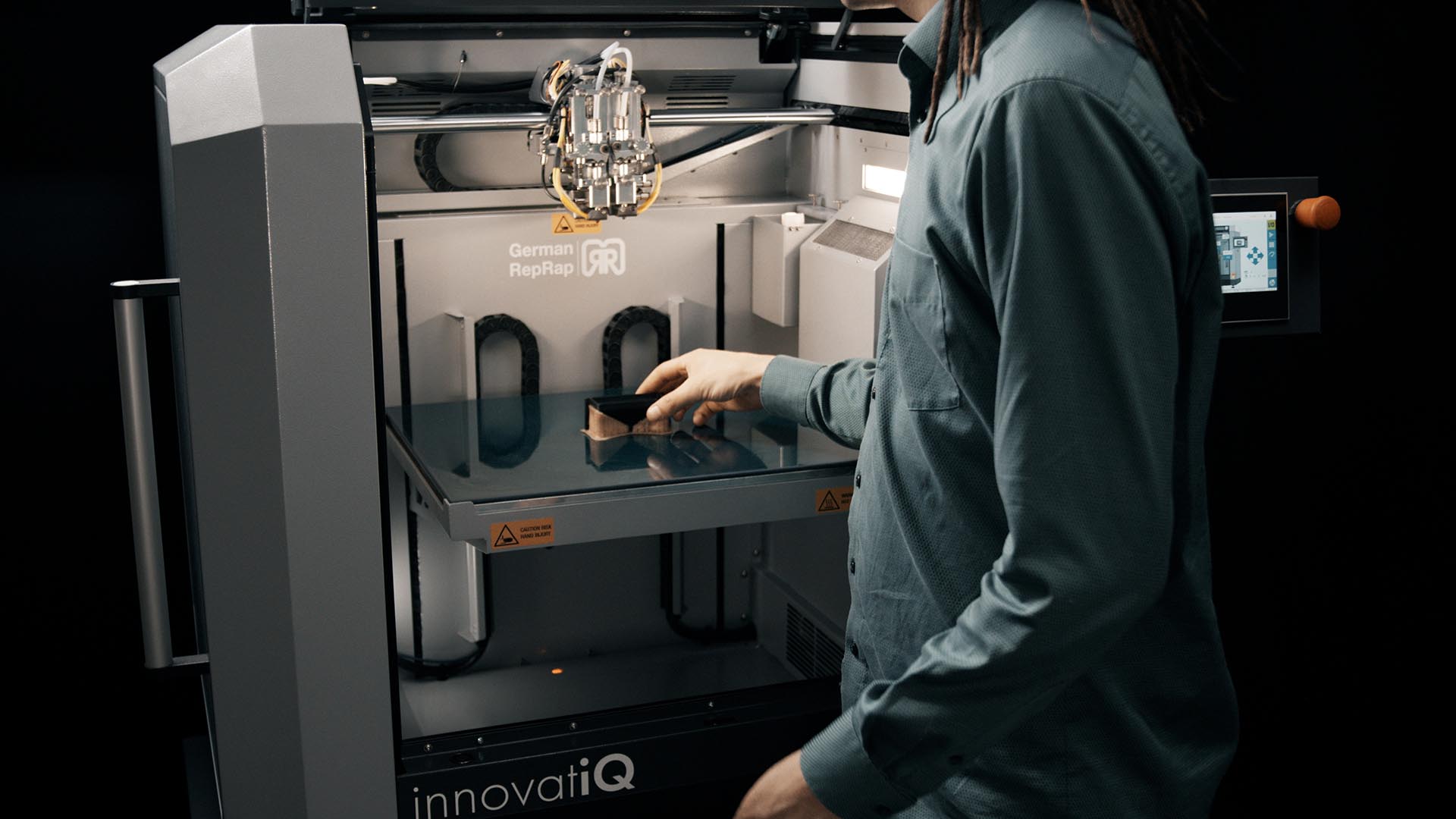

The TiQ 5 is the optimal system solution for additive manufacturing of large functional parts. The unique SmartFunctions ensure intuitive and user-friendly use of the complex possibilities of additive manufacturing.

Equipped with a build space heater and a water-cooled dual print head, the TiQ 5 enables the process-reliable production of components made of a wide range of materials, especially high-performance thermoplastics. Whether for one-off production, large prototypes or industrial manufacturing – the TiQ 5 is always the right choice!

- GestiQ Pro: innovative control with integrated SmartFunctions

- SmartSpeed: intelligent dynamic material feed for optimum printing speed

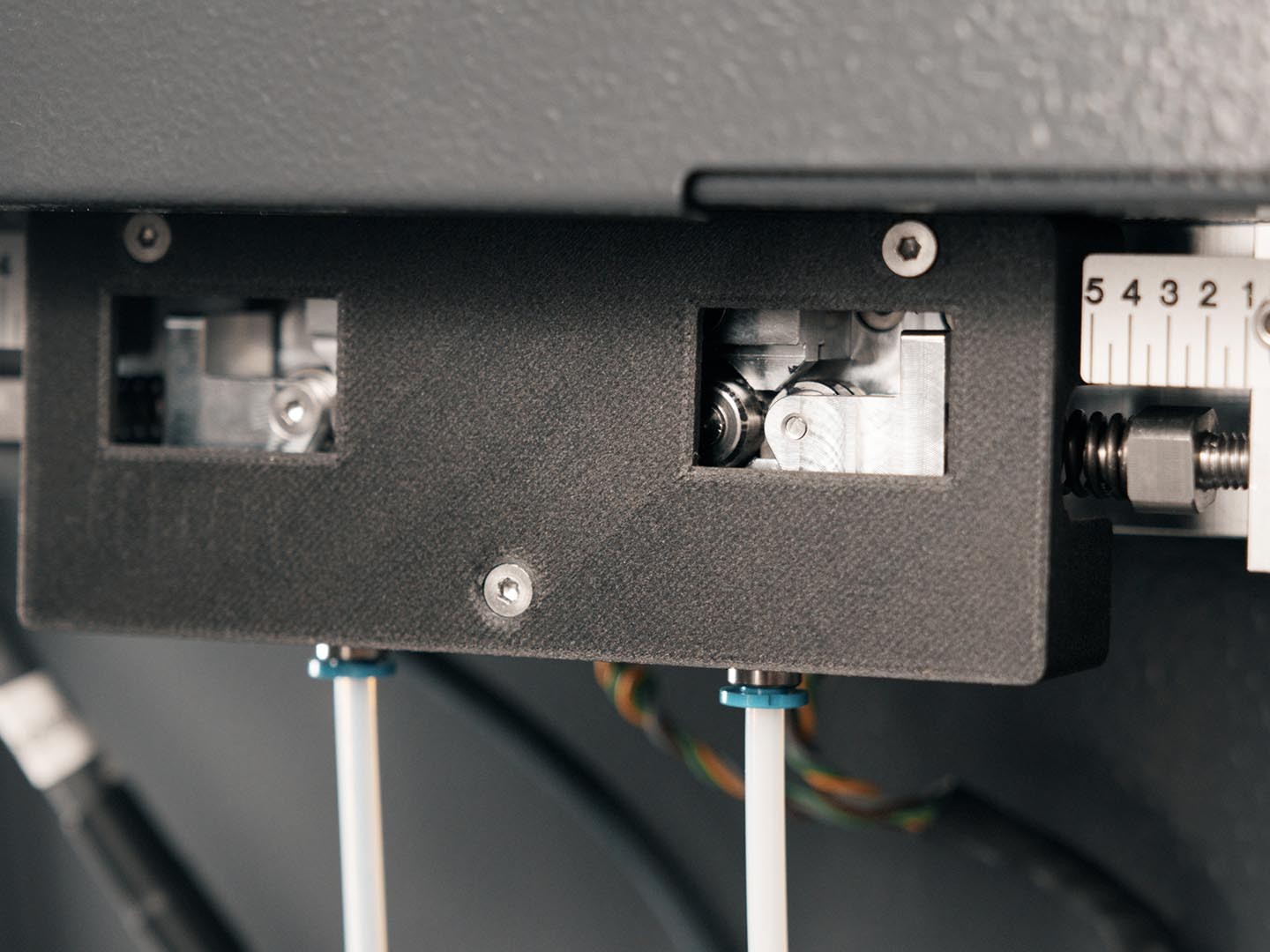

- SmartTrack: sensor-controlled filament feeding for reliable precision and process reliability

- SmartStart: fully automatic print bed leveling for seamless print jobs

- Optional:Material drying unit (MiQ 5) can be integrated (Highly recommended).

Technical features

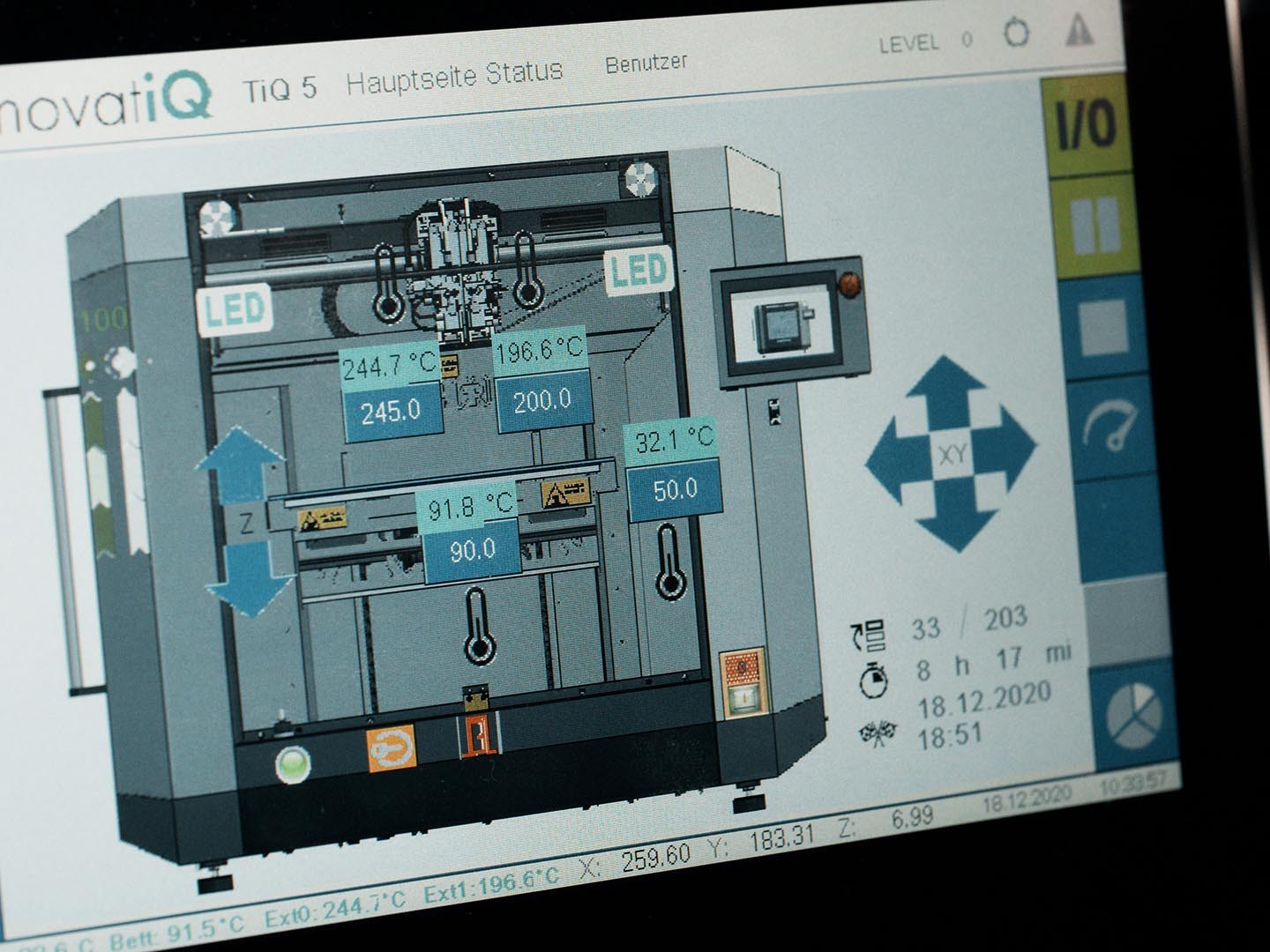

GestiQ Pro is the new Human Machine Interface (HMI) from innovatiQ. The innovative industrial control supports the user with integrated SmartFunctions.

SmartStart: Laser-assisted print bed leveling ensures optimum adjustment of the print bed.

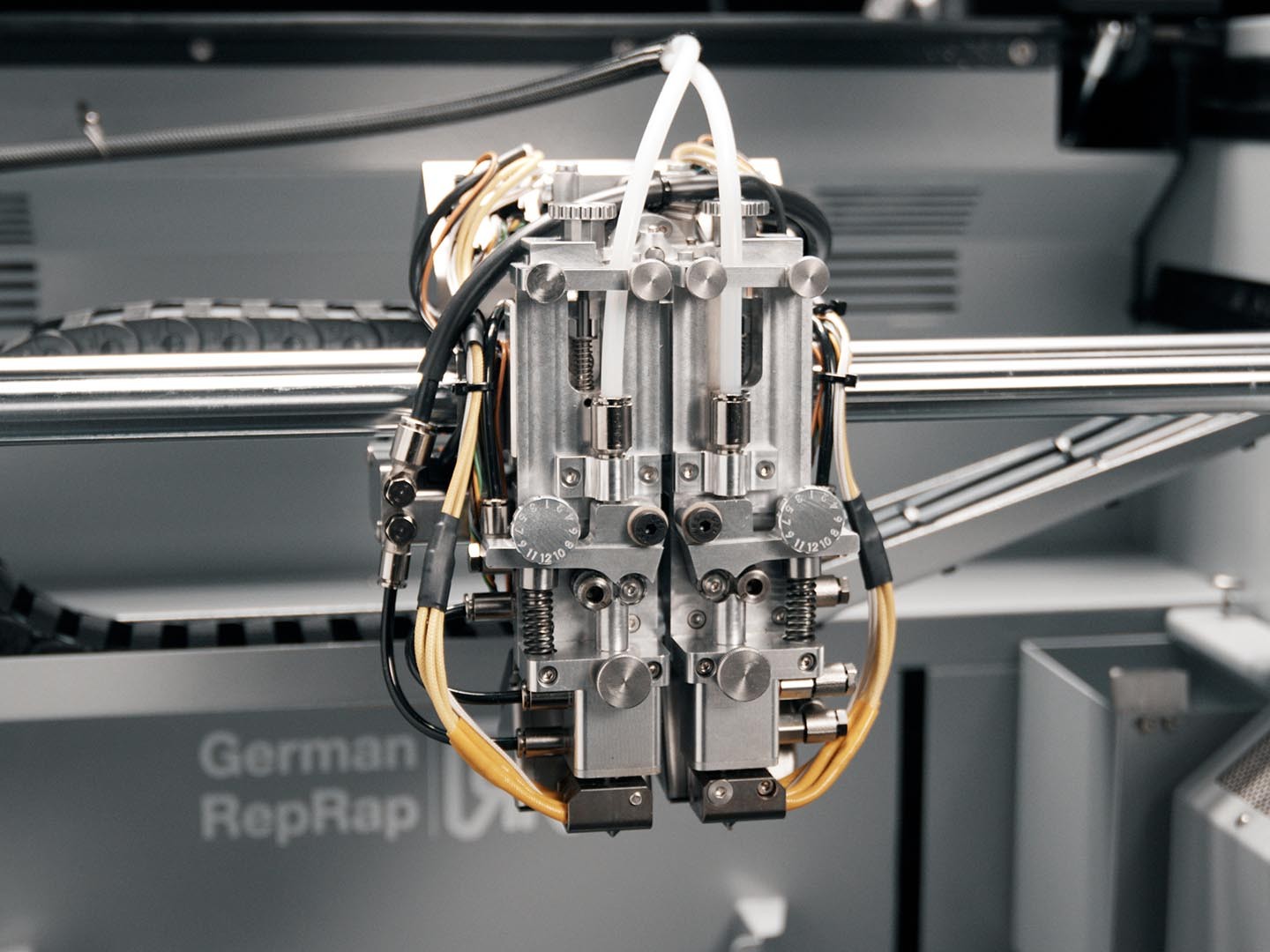

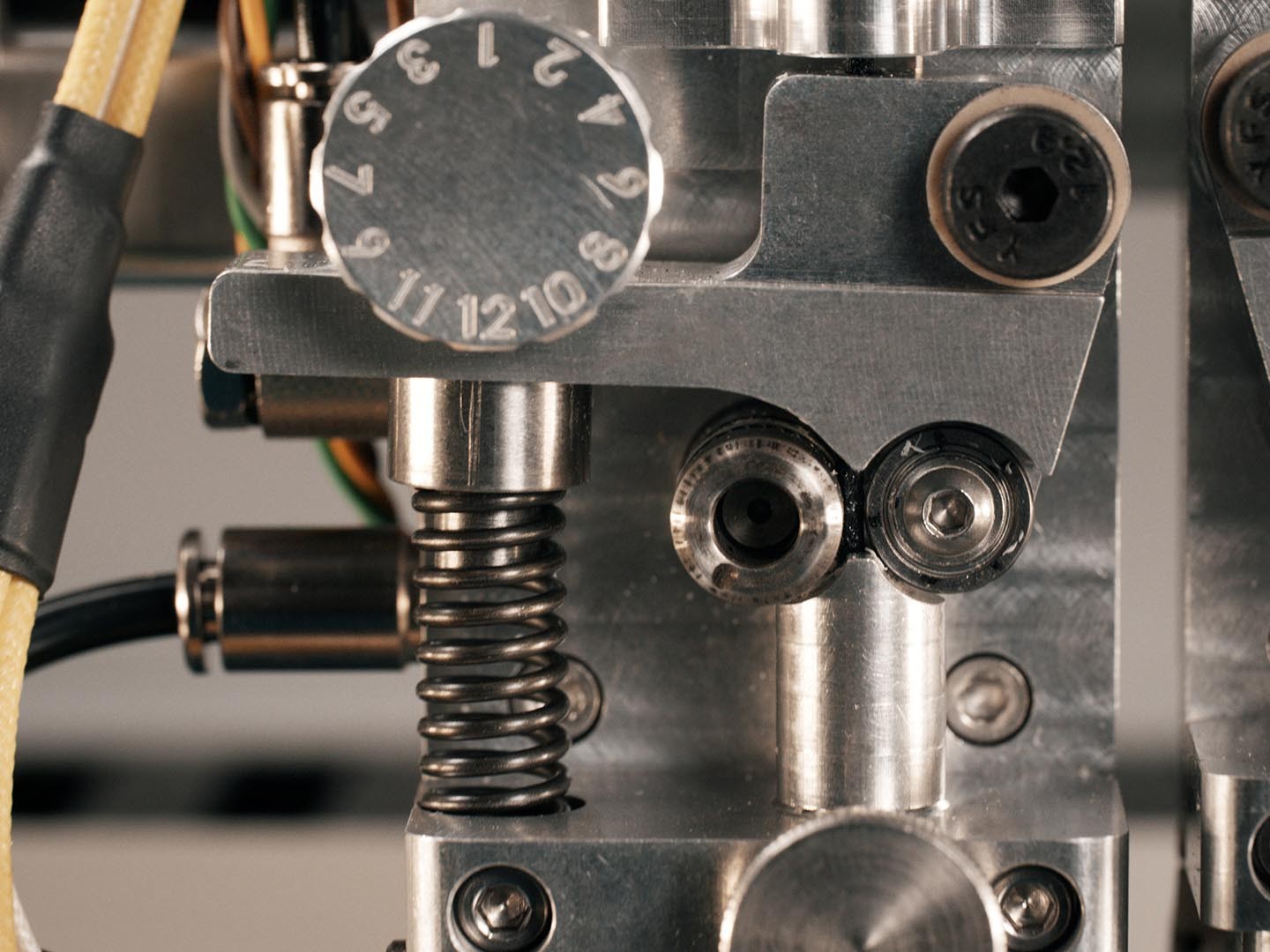

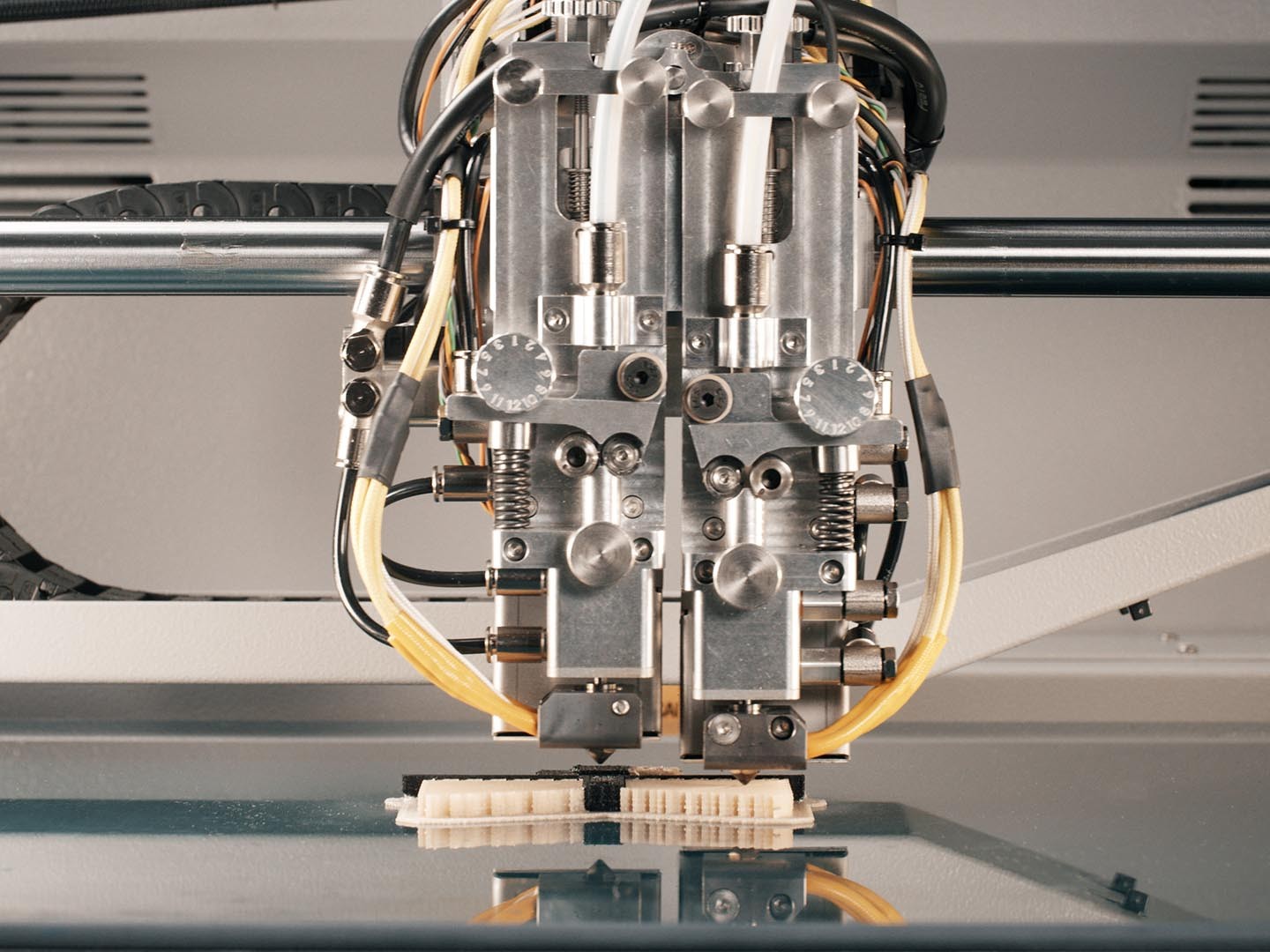

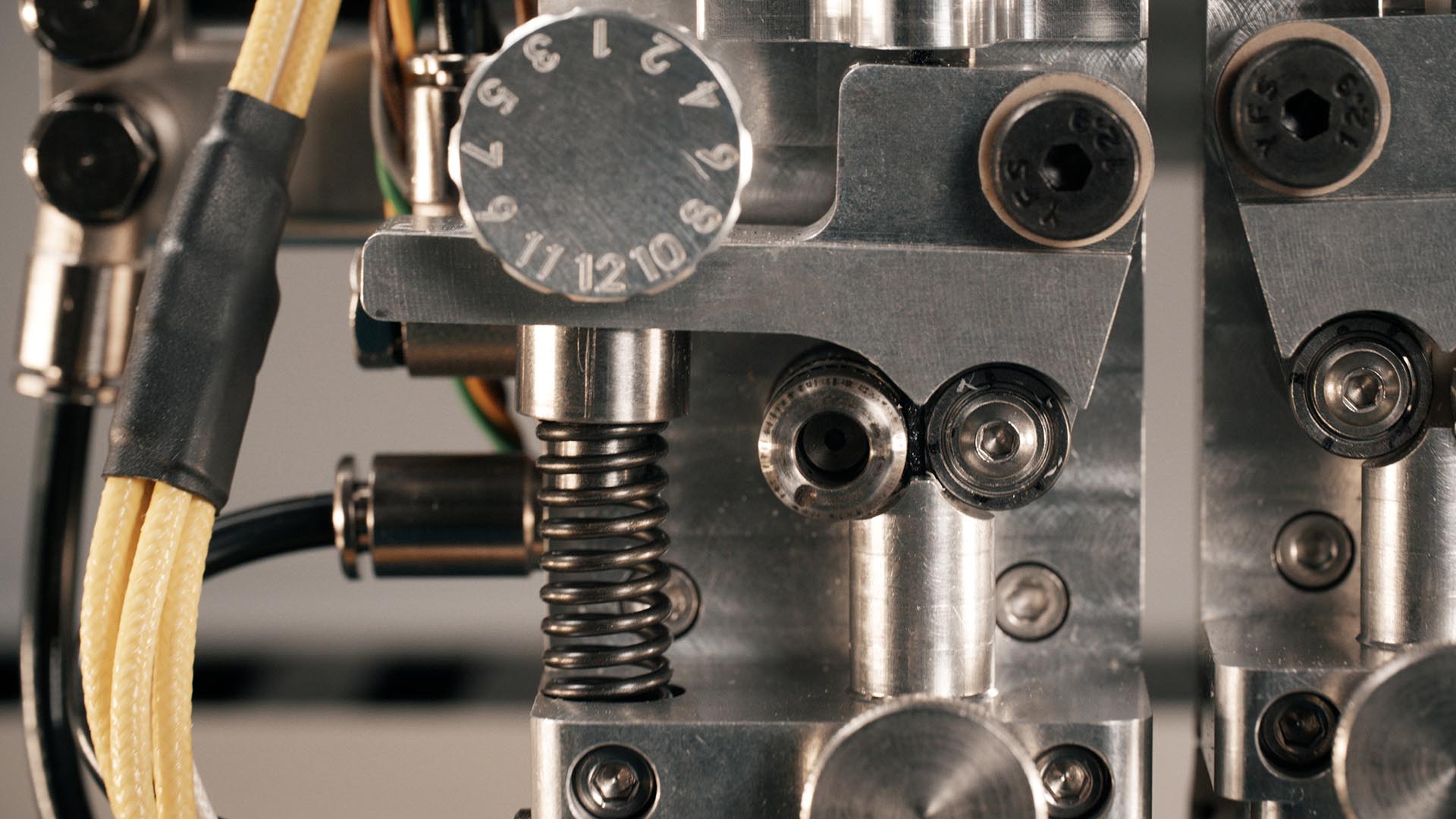

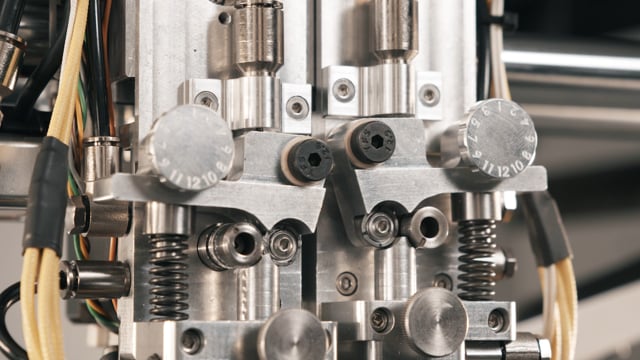

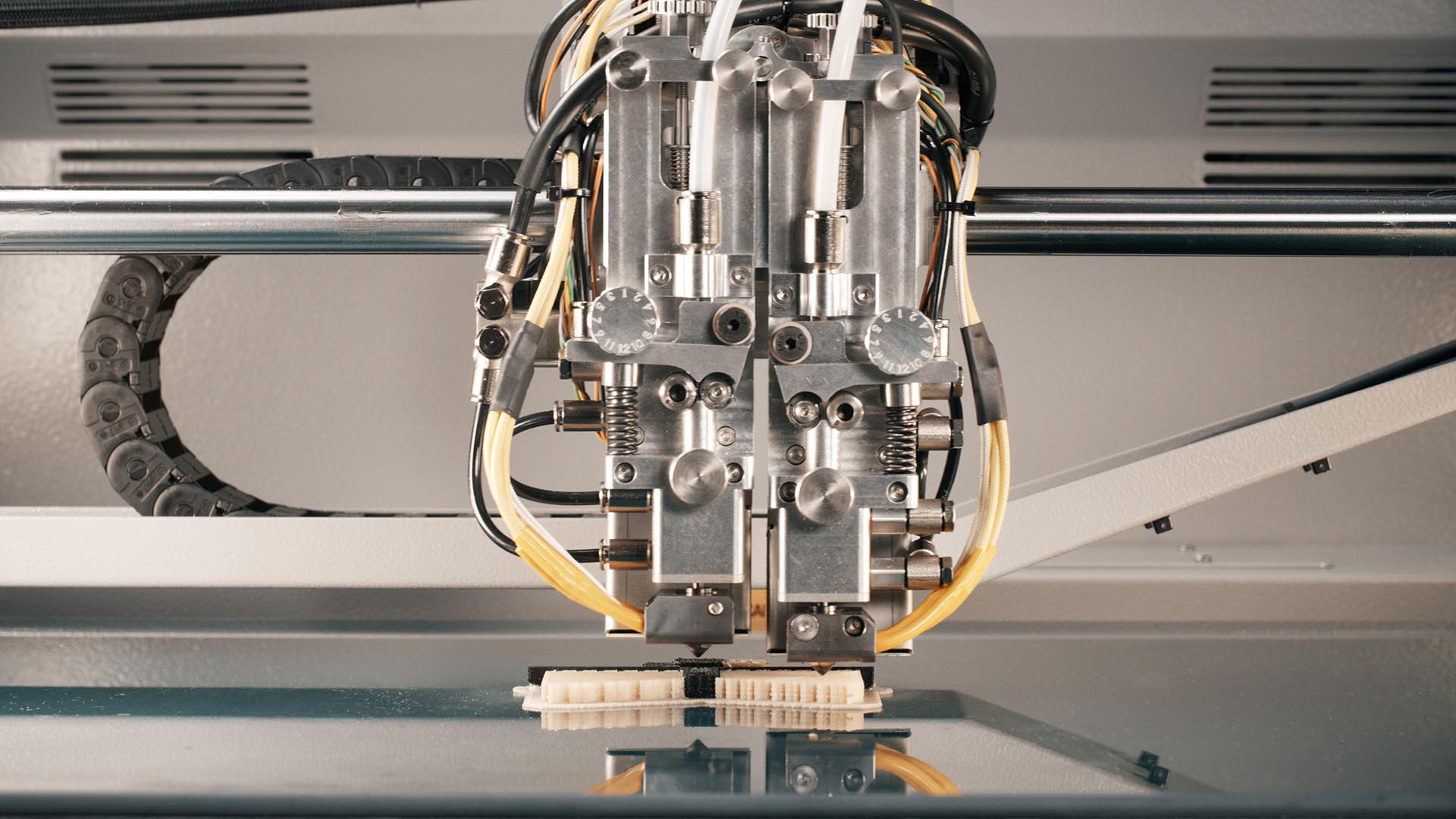

The nozzle technology developed in-house by innovatiQ enables the TiQ 5 to process fiber-reinforced, abrasive materials.

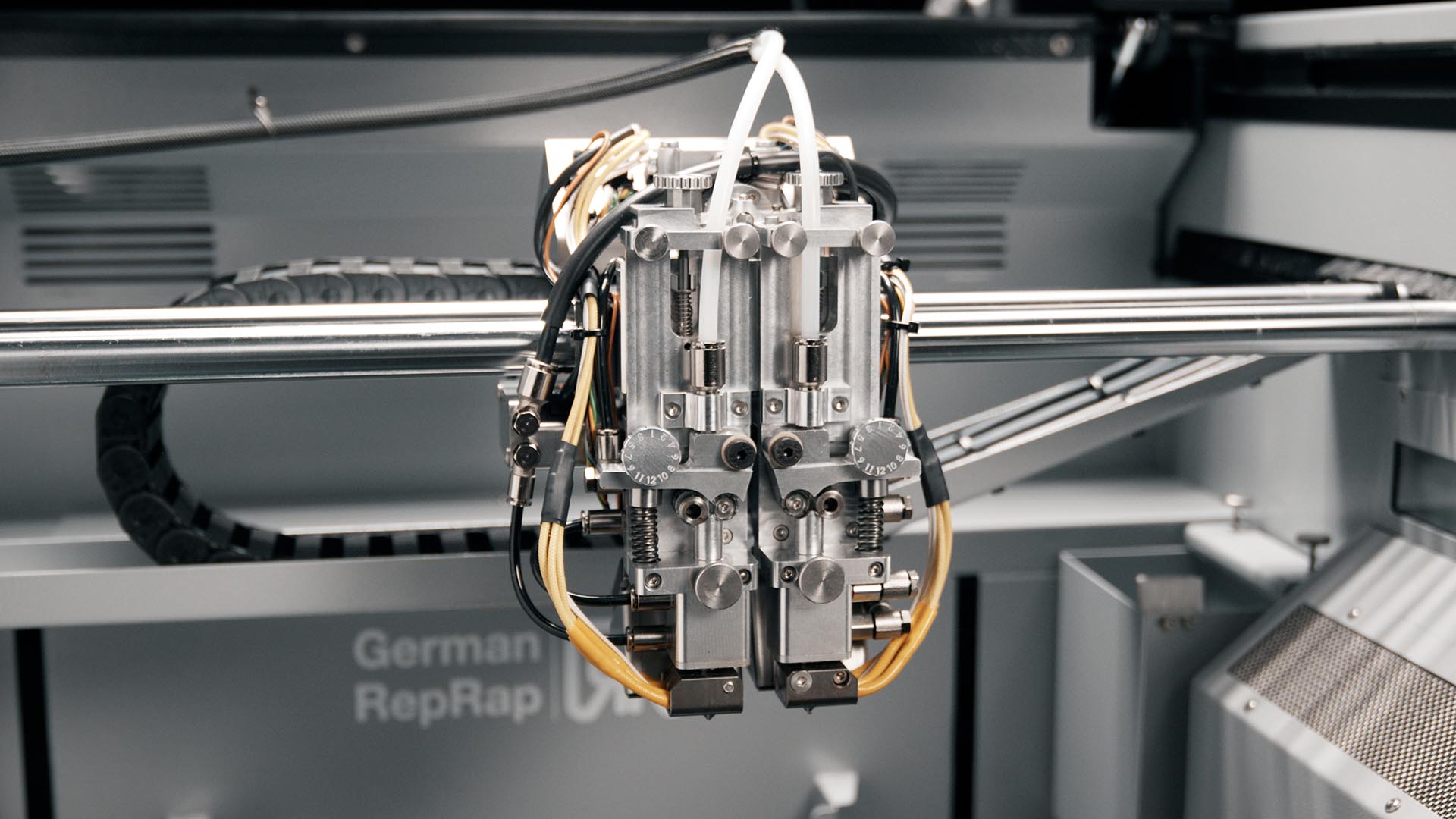

The dual-lift function increases process reliability. The upward movement of the non-extruding print head prevents collisions and material contamination.

Water cooling in the dual-lift printhead ensures consistent quality, even when using materials with high processing temperatures and a long print time.

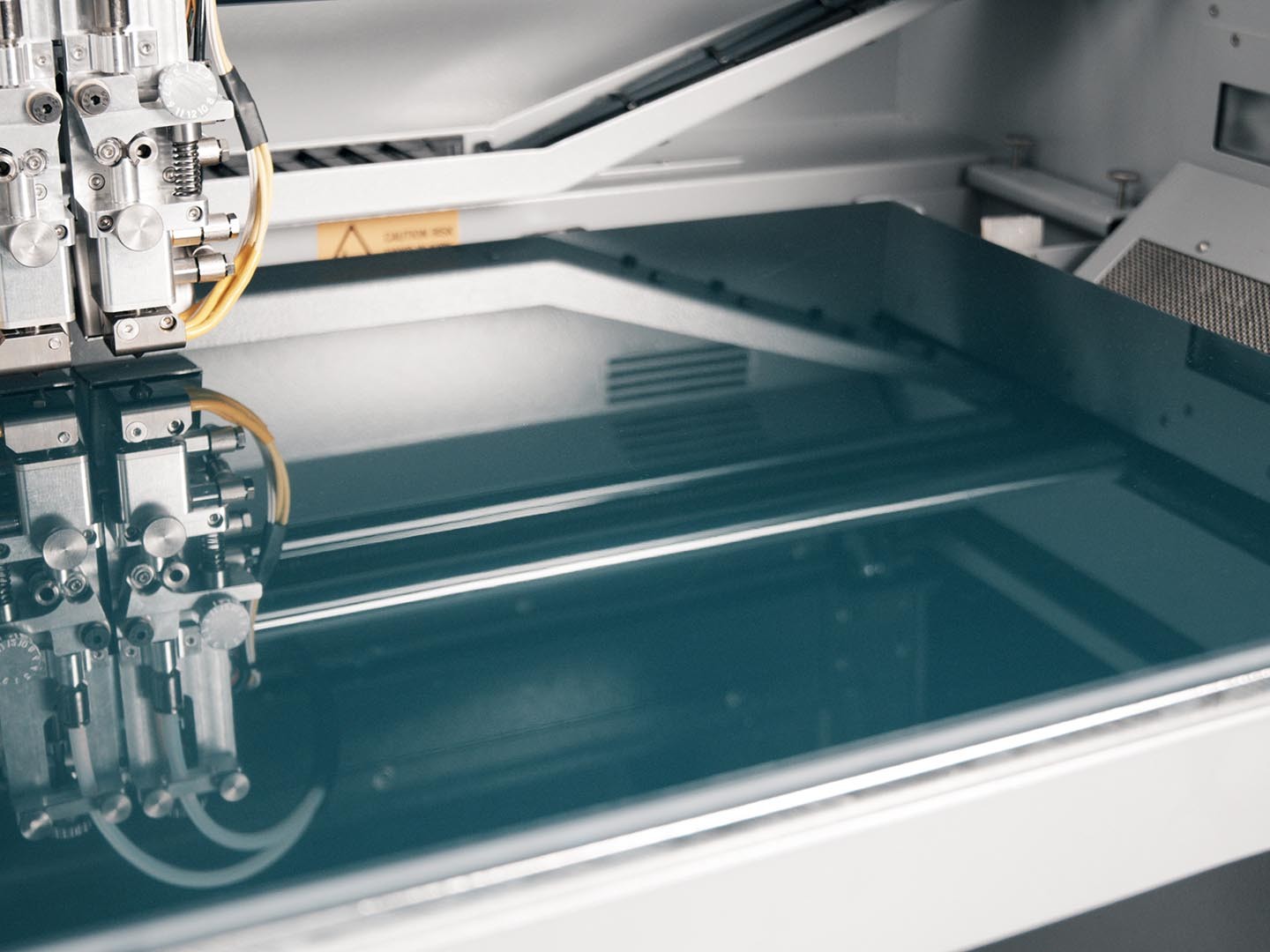

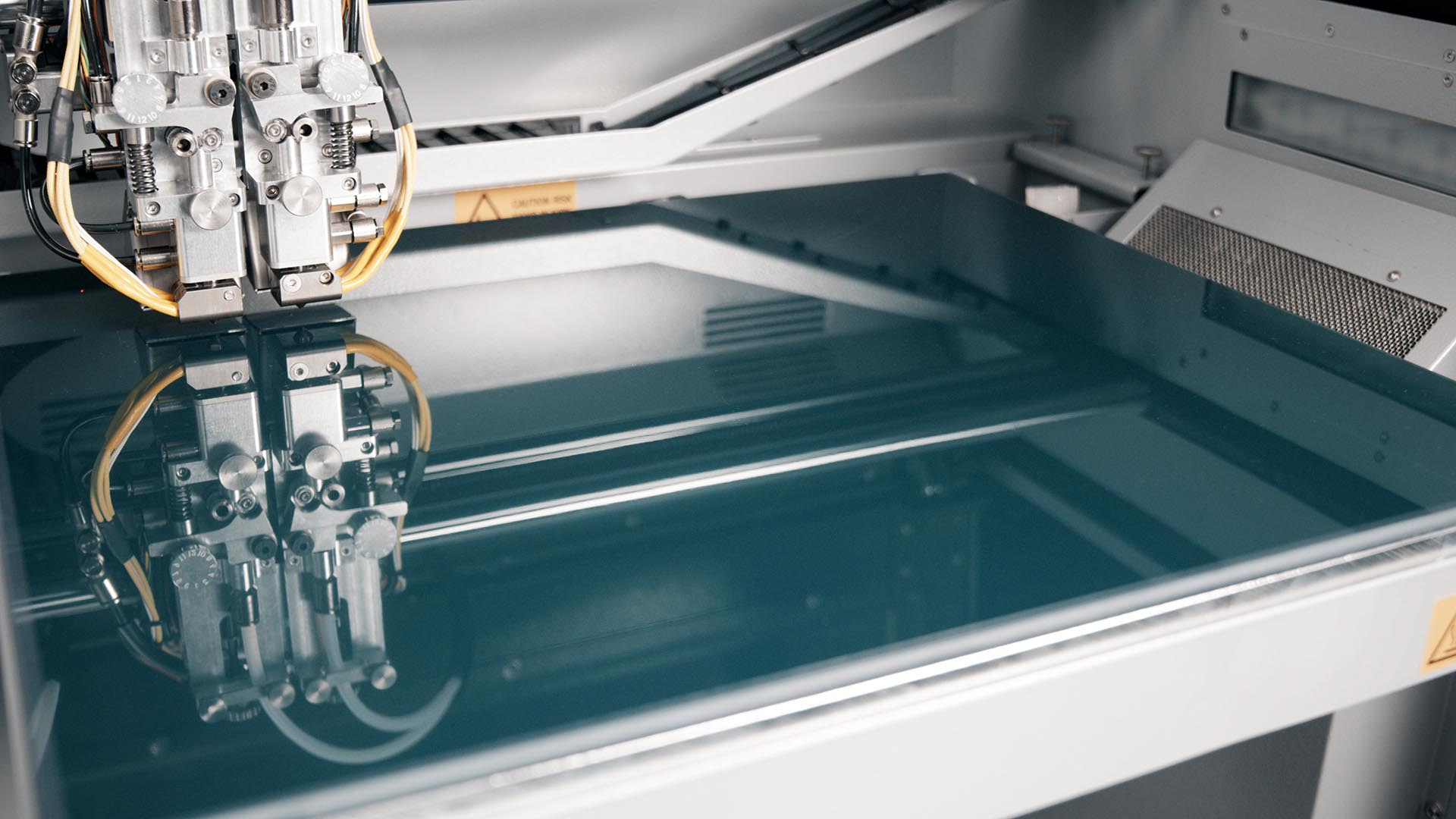

Heated ceramic print bed

The 6mm thick glass ceramic print bed can be heated up to 160°C, and is characterized by improved adhesion of the material to the print bed. This increases both the process quality and the accuracy of fit in the produced component.

The high-quality print bed rests on a cast aluminum plate, which ensures homogeneous heat distribution and remains free of deformation even at the highest temperatures. The easiest way to remove the finished component is to remove the print bed with the produced component from the printer in one easy step.

Process-controlled component heating.

The TiQ 5 is designed for a wide variety of materials and optimized for the production of components made from high-performance thermoplastics. These include filaments with technical properties such as composite materials, high-temperature or UV resistance, or special hardness due to fiber additives.

The temperature in the build space can be raised to up to 80°C within a short time and remains reliably stable even in continuous operation. The water-cooled high-temperature dual print head (up to 400°C) ensures process-reliable processing of demanding materials and is thus ideally suited for the production of heavy-duty components and functional models.

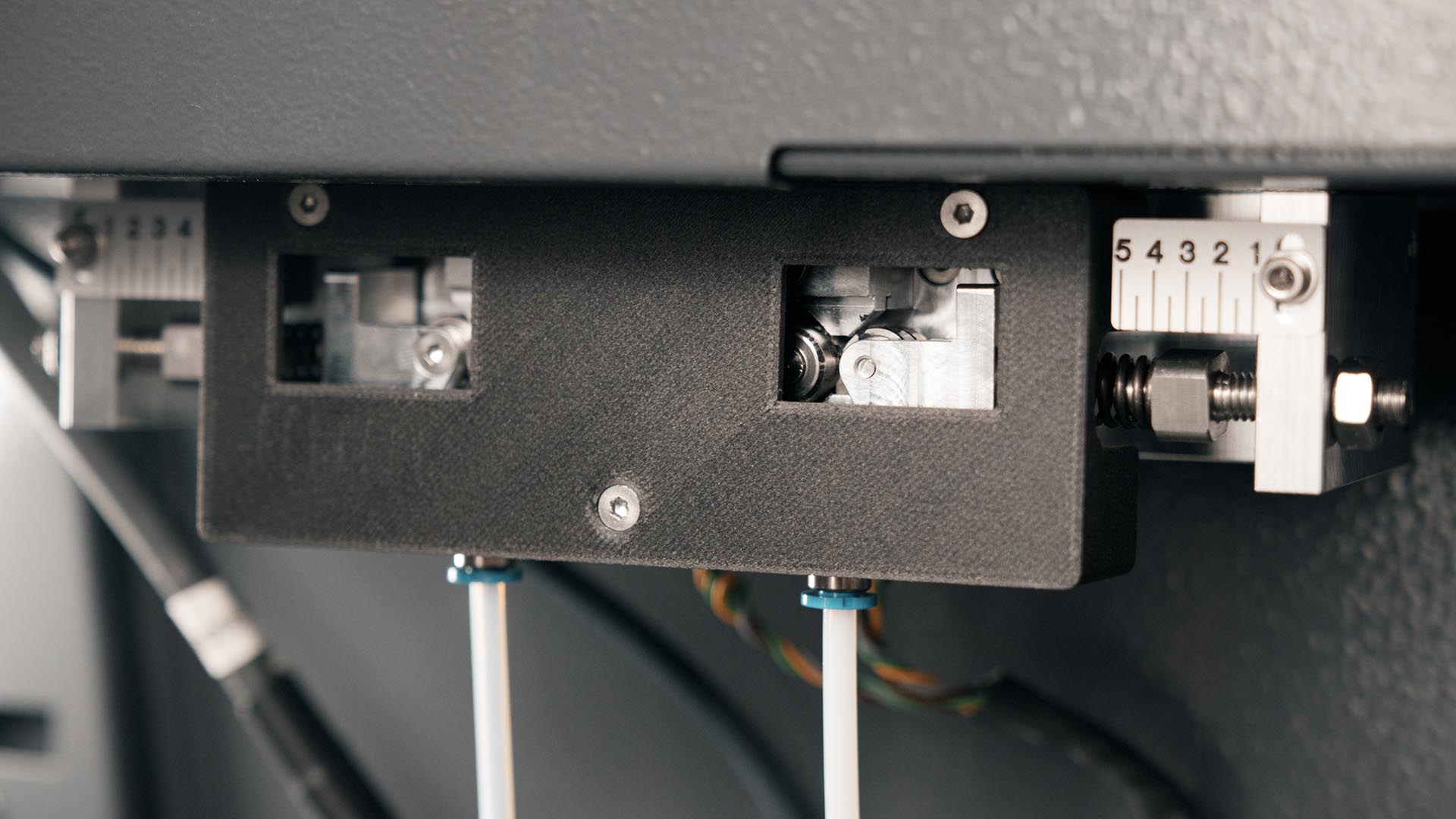

The SmartSpeed anti-slip control and the SmartTrack intelligent filament tracking system ensure maximum process reliability in additive manufacturing.

Direct Drive ensures a printing process without interruption in the material supply. The result: Best performance with maximum process reliability!

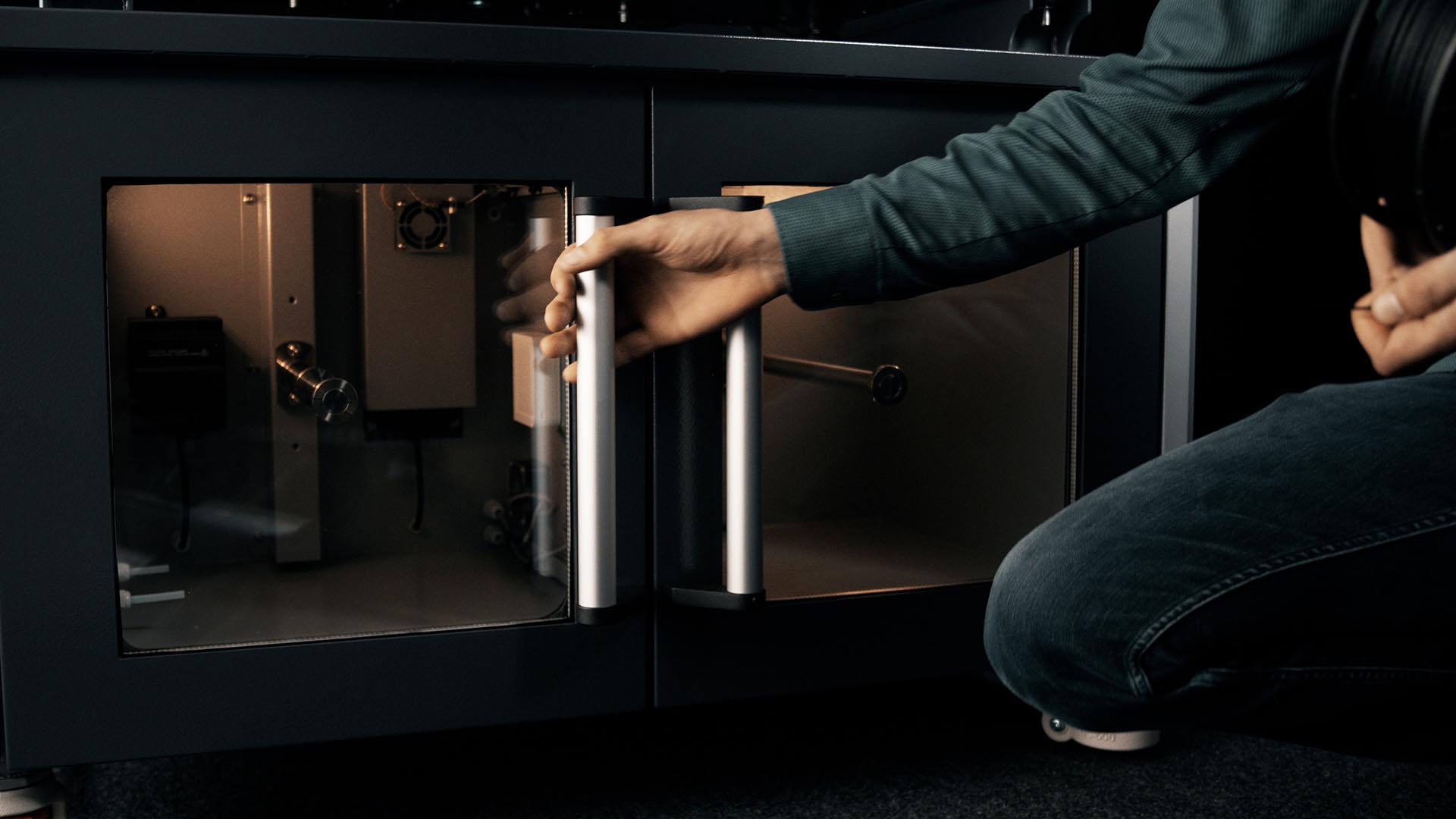

Highest component quality requires optimum storage and maximum possible drying of the material. For this purpose, innovatiQ has developed the innovative MiQ 5 material drying unit for the TiQ 5.

The pivoting wing panels allow direct and ergonomic access to the installation space.

Safety concept according to industry standards

The TiQ 5 is equipped with a comprehensive safety concept in accordance with industry standards. The foot switch enables controlled and safe intervention in the system while the process is running. This can be used, for example, to fine-tune the control loop of the printing parameters.

Network and electronics for demanding users

All the electronics of the TiQ 5 are housed in a special electrical cabinet. The GestiQ Pro control system can be operated intuitively via the 7-inch touchscreen. The network connection is established via Ethernet, allowing remote access and monitoring via tablet, smartphone or computer. Print jobs can be started directly via a USB stick or the browser-based control.

Technical data

- Print space* (X/Y/Z): 500 x 400 x 450 mm

- HMI: GestiQ Pro V1.05

- Print speed**: 10 – 150 mm/s

- Traverse speed**: 10 – 300 mm/s

- Repeatability** (X/Y): +/- 0.1 mm

- Layer thickness** (min.): 0.02 mm

- filament / nozzle diameter: 1.75 mm / 0.40 mm

- standard nozzle: 0.40 mm

- additional nozzle options: 0.25 | 0.30 | 0.50 I 0.60 I 0.80 mm

- Extruder: water-cooled DD4 Dual-Lift (operating weight 4 kg)

- Temperature extruder up to 400°C (+/- 2%)

- Temperature process chamber: 80°C

- Temperature printing plate: 160°C

- Data exchange: stand-alone printing with touch display or network compatible

- Software equipment: Simplify3D

- Power consumption (max.) 2.3 kW, 20-30% in continuous operation

- Connected load: 230 V, 16 A

- Display: 7 inch touch

- Outer dimensions (W/D/H): 1120 x 850 x 955 mm

- Weight: approx. 185 kg (without material drying unit)

- Technology: FFF (Fused Filament Fabrication)

* Utilization of full building area is only possible with primary extruder (left).

** Deviations depending on equipment/material/process

Service & Support

Would you like a personal consultation or an individual offer for this system?

With pleasure! Contact our Service & Support Team for a personal handling of your request.