Additive manufacturing with the x500 for customized ride comfort

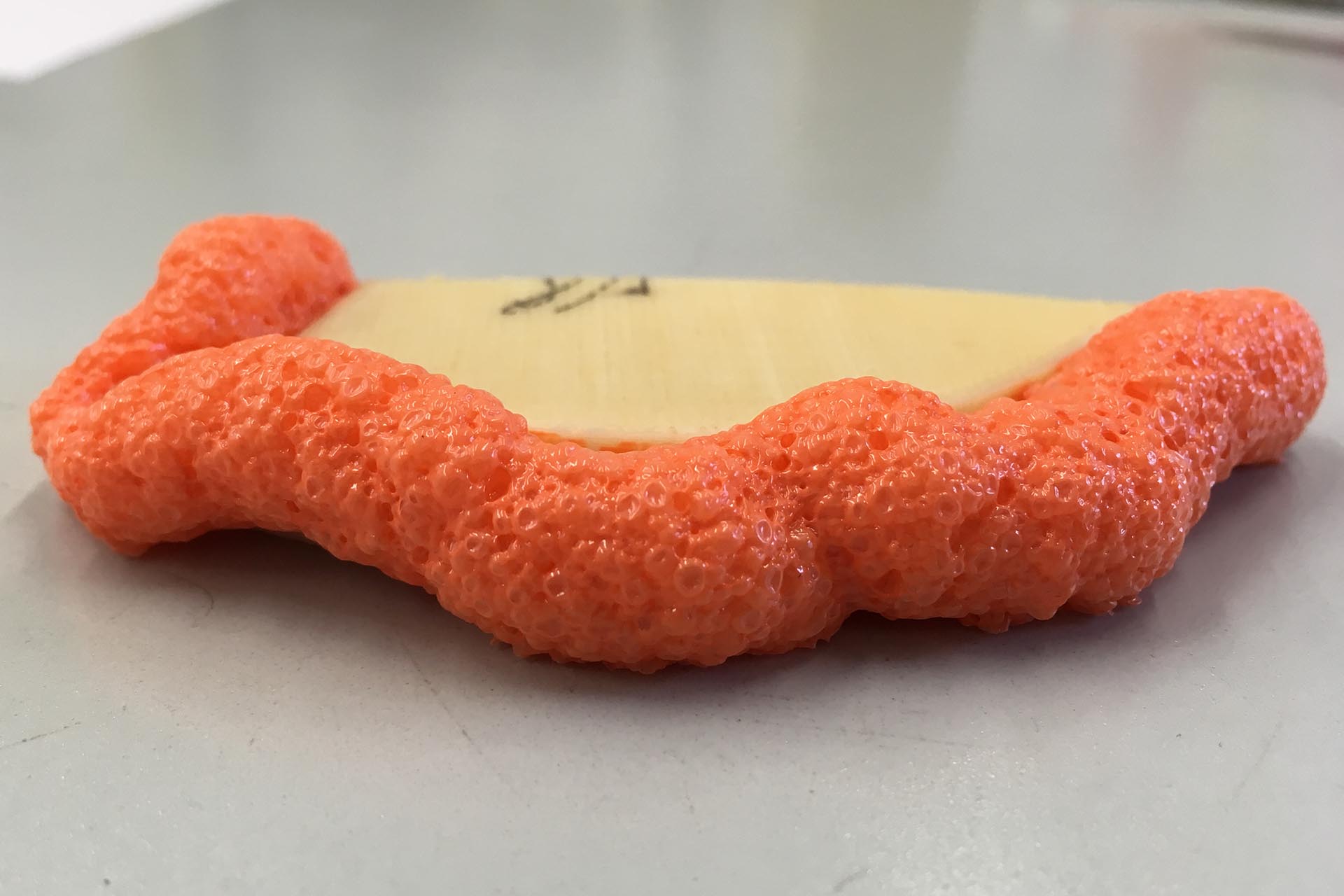

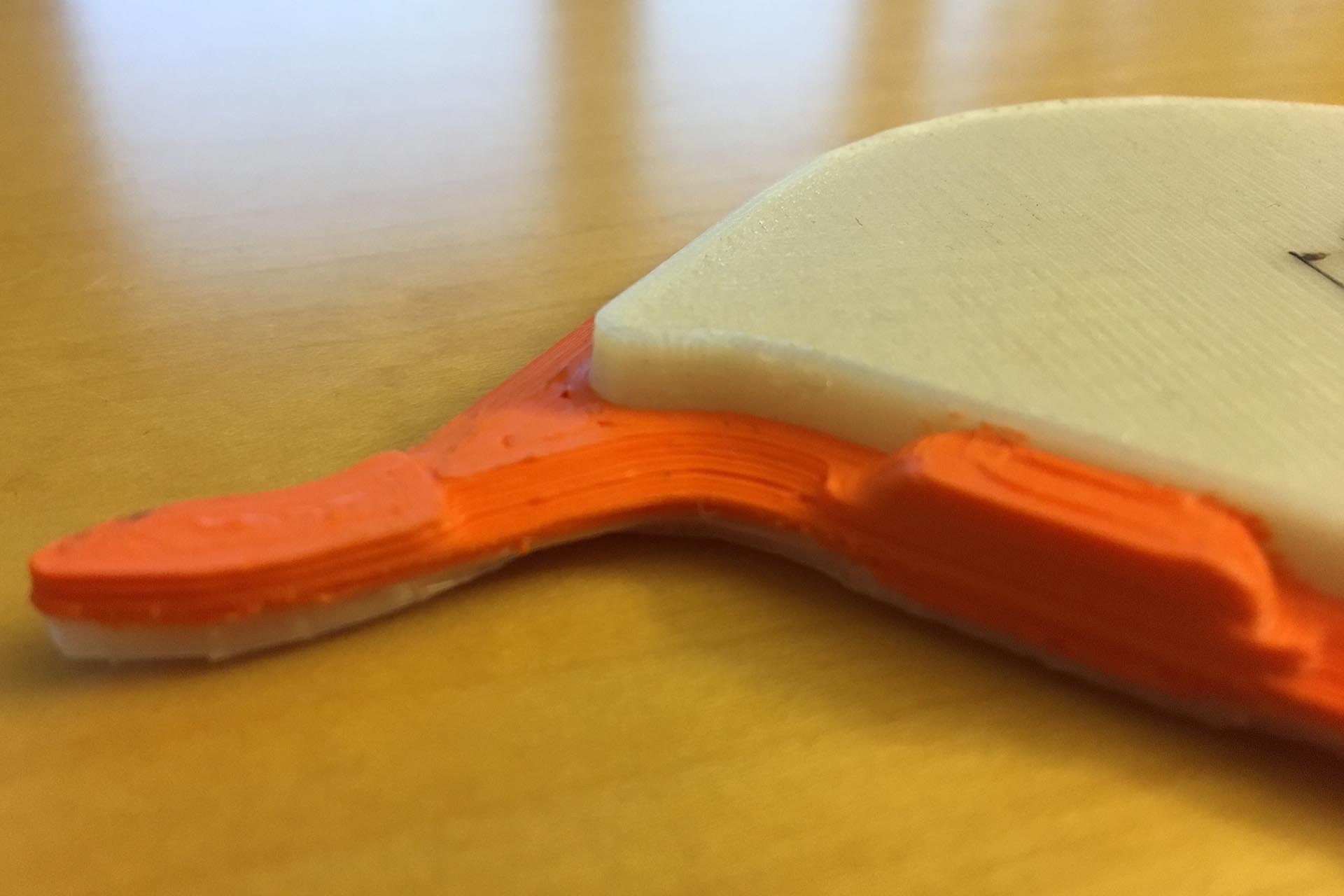

The company also benefits from new possibilities in terms of materials and design thanks to the wide range of customization solutions. Most current mid- or luxury-class vehicle models fascinate with their sophisticated acoustics and impeccable interior air quality. In order to protect the occupants from dust, moisture and disturbing noises, various car manufacturers rely on high-tech materials from Sika Automotive in the area of car body production. The specialist of solutions for bonding, sealing, damping and reinforcing car bodies supplies OEMs with extremely strong and lightweight chassis components. For a pilot project, Sika Automotive developed a plastic part that is installed in the lower area of the A and B pillars of a premium vehicle. Made of stable polyamide and the elastic SikaBaffle® , the component has a complex shape. The component obtains its sealing and damping function with SikaBaffle® printed on the edges, which expands by means of an e-coat process – applied in a subsequent assembly process – and thus seals the edge regions.

As a rule, body structures are modified five to ten times between the first vehicle prototype and the pilot series. This also applies to the component mentioned: Here, several prototypes had to be produced before the German RepRap x500 was used. With each change to the geometry of the body structure, the plastic part also had to be redesigned in each case. This meant that new injection molds had to be made for each adaptation – a major effort considering that several hours were needed to produce such a mold.

To shorten the development phases, Sika Automotive looked for a fused filament fabrication (FFF) printer that could handle third-party filaments. At the AMX 2018 additive manufacturing trade show, the company came across KVT-Fastening, which carries a comprehensive portfolio of professional 3D printing solutions, including from 3D printer manufacturer German RepRap.

Due to the high demands on the printing process, KVT-Fastening and German RepRap worked together with the customer Sika Automotive to develop a customized solution. In the process, the German RepRap x500 was modified to be optimally adapted to the processing of the heat-reactive thermoplastic SikaBaffle®, as this is too soft for most extruders. Thanks to the open material platform of the x500, the printing parameters could be precisely adapted to the special thermoplastic.

Sika Automotive and German RepRap conducted successful tests with the FFF printer during 2018 and achieved the required high process reliability. KVT-Fastening accompanied the pilot project and delivered the first of the two x500 printers ordered in December 2018. The fact that Sika Automotive now produces these components directly using dual printing shortens the development phases of such plastic components for the company.

The application of efficient FFF technology, including the associated processing of technically demanding materials, opens new doors for Sika Automotive. For example, the company can now supply its plastic parts for smaller series. In addition, the materials specialist can also design the design of its components more freely thanks to the new possibilities offered by the use of 3D printing. Thanks to the carefully thought-out “Direct Drive” system, the German RepRap x500 is capable of printing a wide range of different materials. For Sika Automotive, this marks the start of a new design era which, together with the specially developed materials, brings with it great potential.

KVT-Fastening is able to customize any 3D printer from its portfolio to meet the customer’s individual needs. The team of specialists accompanies the customer throughout the entire set-up process – from consulting and initial testing to installation and complete servicing of the equipment.